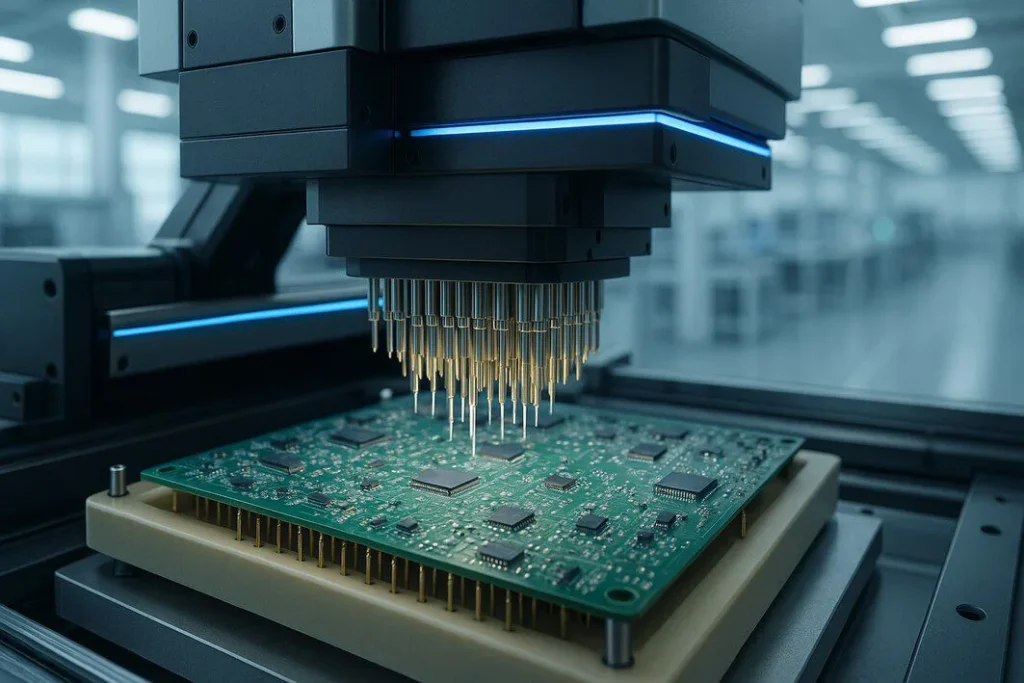

In the world of electronics manufacturing, reliability is not just a feature—it’s the foundation. From complex industrial controllers to the everyday devices in our homes, the performance of a product hinges on the integrity of its Printed Circuit Board (PCB). But how can you guarantee that every single component on a board is correctly placed, connected, and valued before it ships? This is the central question that leads us to a critical manufacturing process. So, what is in circuit testing? In-circuit testing (ICT) is a vital aspect of this process.

Table of Contents

In simple terms, in-circuit testing is an automated test that verifies the electrical connections and the individual components of a populated PCB. It’s a powerful quality control method that checks for manufacturing defects immediately after assembly, ensuring each board meets its exact design specifications. This guide provides a complete overview of ICT, its procedures, and its indispensable role in modern electronics production.