Navigating the world of electronics manufacturing requires a keen eye on both quality and cost. When it comes to ensuring the integrity of printed circuit board assemblies (PCBAs), In-Circuit Testing (ICT) stands as a critical gatekeeper. But a primary question looms for every production manager and engineer: what is the actual ICT machine price? The answer isn’t a simple number, but a complex calculation based on your specific production needs.

Table of Contents

This guide provides a comprehensive cost and pricing analysis for 2025 to demystify the in-circuit tester cost. We will break down the key factors that determine the final price, explore hidden costs, and help you understand the return on investment (ROI) for this essential piece of automated test equipment.

What is an In-Circuit Tester (ICT) and Why is it Essential?

Before diving into pricing, it’s crucial to understand what an ICT machine does. An in-circuit tester checks a PCBA for manufacturing defects by measuring individual components while they are still “in-circuit.” It verifies shorts, opens, resistance, capacitance, and other basic electrical properties, ensuring that each component was placed correctly and is functioning as intended.

In high-volume production, ICT is not a luxury; it’s a necessity. It catches defects early, preventing faulty boards from moving down the production line, which saves immense costs associated with rework, field failures, and brand reputation damage.

The Core Question: What is the Average ICT Machine Price?

So, what can you expect to pay? The price range for an ICT machine is incredibly broad, typically falling anywhere between $30,000 for a basic, low-node-count system to over $500,000 for a highly advanced, automated machine from a top-tier manufacturer.

This wide spectrum exists because an ICT machine is not an off-the-shelf product. It’s a configurable system tailored to the complexity and volume of the PCBs you produce. The final automated test equipment price depends on a combination of hardware capabilities, software features, and support packages.

Key Factors Influencing In-Circuit Tester Cost

To get a realistic estimate, you must analyze several key variables. Each of these components adds a layer to the final cost.

System Type: Flying Probe vs. Bed-of-Nails

The most significant initial cost differentiator is the type of ICT system:

-

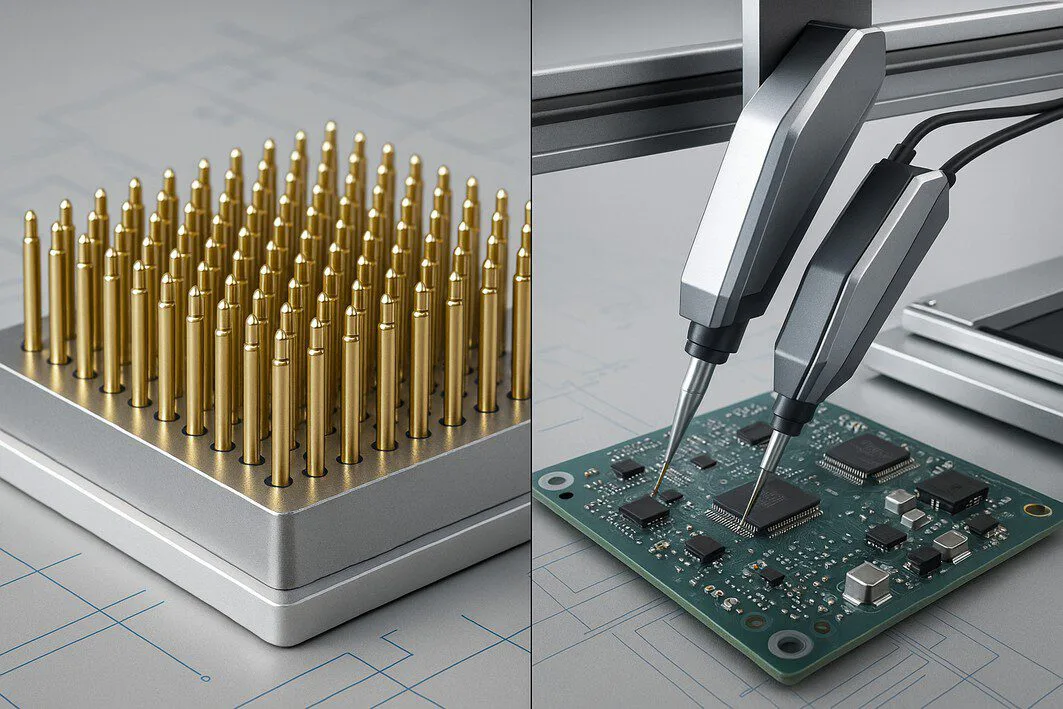

Bed-of-Nails Testers: These are the traditional workhorses for mass production. They use a custom fixture filled with pogo pins that make simultaneous contact with all test points on the board.

- Machine Cost: Generally lower than flying probe systems.

- Fixture Cost: This is a major recurring cost. Each unique PCB design requires a custom, expensive fixture ($5,000 – $30,000+).

- Best For: High-volume, low-mix production where the cost of the fixture can be amortized over tens of thousands of units.

-

Flying Probe Testers: These systems use 2 to 8 robotic probes that move around the board to test points sequentially.

- Machine Cost: Higher initial investment compared to bed-of-nails machines.

- Fixture Cost: None. This is their primary advantage, making them ideal for prototyping and low-to-mid-volume production.

- Best For: High-mix, low-volume environments and new product introduction (NPI) where flexibility is key.

Node Count and Test Point Capacity

The “node count” refers to the maximum number of test points the machine can handle simultaneously. A simple PCBA might only have 500 test points, while a complex server motherboard could have over 5,000. As the required node count increases, so does the internal hardware complexity and, consequently, the in-circuit tester cost.

Test Capabilities and Features

A basic machine checks for shorts, opens, and passive component values. However, modern PCBAs often require more advanced testing, and each additional feature adds to the price tag:

- Boundary Scan (JTAG): Essential for testing integrated circuits (ICs) without direct physical access to their pins.

- On-Board Device Programming: The ability to program firmware onto microcontrollers or flash memory during the test cycle.

- Functional Test Integration: Some ICT systems can perform limited powered-up functional tests, combining two test stages into one.

- RF Testing: Specialized hardware for testing products with wireless capabilities.

- Automated Optical Inspection (AOI): Integrated cameras to check for component presence, polarity, and placement.

Software, Programming, and Automation Level

The sophistication of the software suite plays a huge role in the overall automated test equipment price. Premium software offers easier test program generation, powerful debugging tools, and statistical process control (SPC) data analysis. Furthermore, the machine’s ability to integrate into a fully automated smart factory line with conveyors and handlers will significantly increase its cost compared to a standalone, manually operated unit.

Hidden Costs to Consider Beyond the Sticker Price

A savvy buyer looks beyond the initial quote. Several other expenses contribute to the total cost of ownership:

- Test Fixture Development: For bed-of-nails systems, this is a significant and recurring expense for every new board revision.

- Programming and Debugging: The engineering time required to develop, validate, and fine-tune the test program is a substantial “soft” cost.

- Maintenance and Calibration: ICT machines require regular maintenance and annual calibration to ensure accuracy, often managed through a support contract.

- Operator Training: Your team will need training to operate the machine and interpret its results effectively.

Navigating Your Testing Strategy

Choosing the right testing equipment is a critical investment decision that directly impacts your production efficiency and bottom line. The complexity of balancing the initial ICT machine price with long-term operational costs and ROI requires deep industry expertise. A comprehensive knowledge base in electronics manufacturing is key to making an informed choice that aligns with your specific product roadmap and volume forecasts.

To fully grasp the strategic importance of this process, it’s beneficial to understand how different testing methods fit into a larger quality assurance framework. For a deeper dive, you can learn more by exploring our comprehensive testing and validation services and their role in modern manufacturing. We provide end-to-end solutions that help you optimize every stage of production.

Conclusion: An Investment in Quality

Ultimately, the ICT machine price should be viewed not as an expense, but as an investment in quality, reliability, and long-term profitability. A lower-cost machine might save money upfront but could lead to higher costs down the line from missed defects and increased rework. Conversely, overspending on a machine with unnecessary capabilities can strain your budget without providing a proportional benefit.

By carefully analyzing your production volume, board complexity, and future needs, you can determine the right balance. The goal is to select a system that provides the most effective defect coverage for your products, ensuring a strong return on investment by safeguarding your product quality and brand reputation for years to come.