In the world of manufacturing and technology, terms like “system assembly” are foundational. But for those outside the industry or just beginning to explore complex products like residential solar solutions, these concepts can seem opaque. If you’ve ever found yourself asking what system assembly is, you’ve come to the right place. This guide will break down the fundamentals, answer key questions, and clarify why this process is crucial for the products you use every day.

Table of Contents

At RenewGenius, we believe in empowering homeowners with knowledge. Our comprehensive solar knowledge base is built on the principle that understanding the “how” behind a product leads to better decisions. Let’s dive into the core concepts of system assembly.

What is System Assembly? A Clear Definition

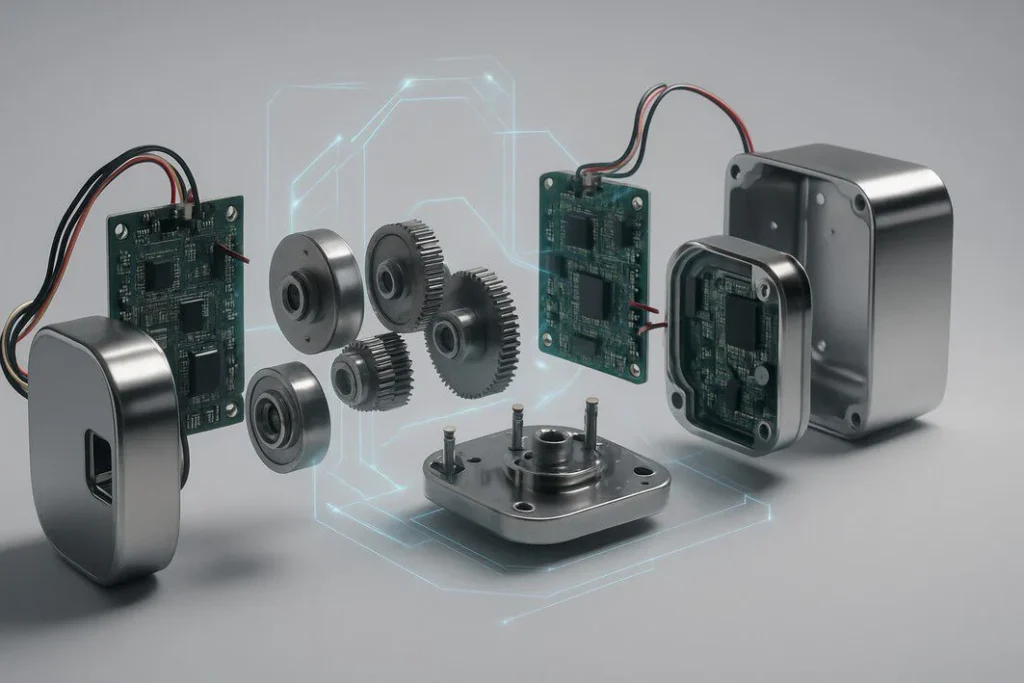

System assembly is the manufacturing process of bringing together various manufactured components and sub-assemblies to create a single, complete, and functional product or “system.” It’s the final stage where individual parts, which may have been produced in different locations, are integrated according to a precise blueprint.

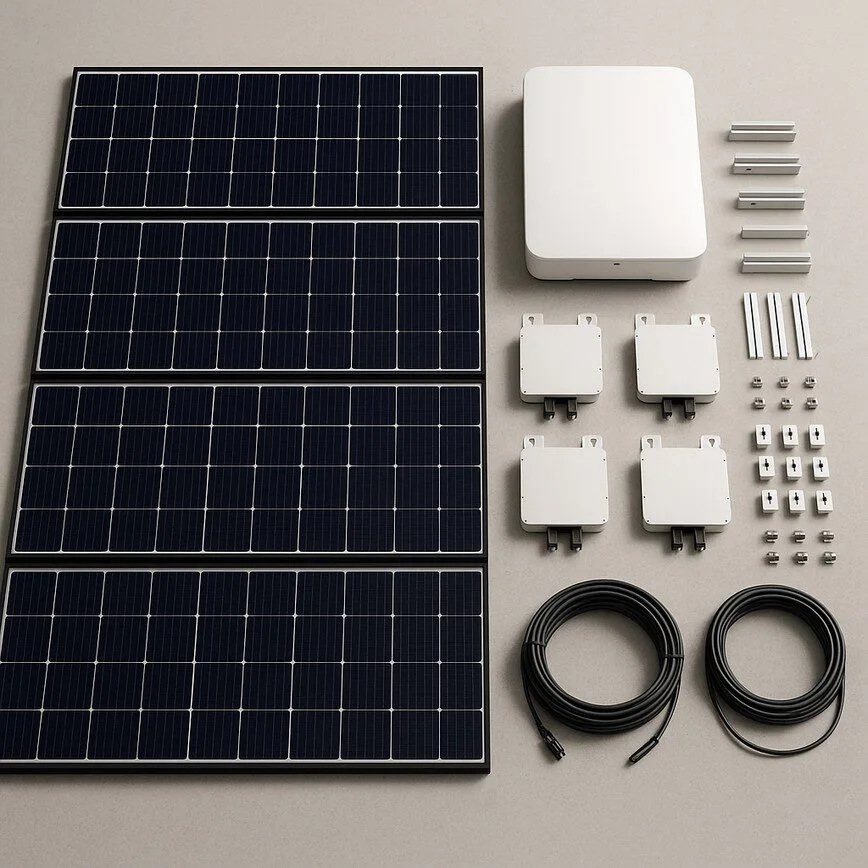

Think of it as the ultimate step in a complex recipe. You have all your ingredients (components) and smaller prepared dishes (sub-assemblies), and system assembly is the process of plating them together to create the final meal. For us, this means taking high-quality solar panels, inverters, racking, and wiring and expertly combining them into a cohesive, power-generating residential solar system.

Unpacking the Meaning of Assembly Equipment

To perform system assembly, you need the right tools. This brings us to the meaning of assembly equipment. Simply put, system or assembly equipment refers to all the tools, machinery, software, and devices used to facilitate the assembly process.

The complexity of this equipment can vary dramatically, ranging from:

- Manual Tools: Screwdrivers, torque wrenches, and soldering irons.

- Automated Machinery: Conveyor belts, robotic arms for “pick-and-place” operations, and automated fastening machines.

- Testing and Calibration Devices: Multimeters, oscilloscopes, and custom software to ensure every component and the final system functions as intended.

The specific answer to “what is system equipment” depends entirely on the product being built. The equipment for assembling a smartphone is vastly different from that used for a car or, in our case, a residential solar solution.

What is an Example of an Assembly System in Action?

To make this tangible, let’s look at an example of an assembly system we know best: installing a residential solar energy system. This is a perfect real-world illustration of system assembly happening right on your property.

- Components Arrive: The individual parts are delivered. This includes solar panels, central or micro-inverters, mounting racks, electrical wiring, and a monitoring unit.

- Sub-Assembly (Racking): The first step is assembling the racking system on the roof. This structure is a sub-assembly that will hold the main components.

- Component Integration: The solar panels are then mounted onto the racks. The inverters are installed and connected to the panels and the home’s electrical panel.

- Final Connections & Testing: All wiring is completed, and the monitoring system is configured. The entire system is then powered on and rigorously tested to ensure it’s generating electricity safely and efficiently.

This entire sequence, from loose parts to a functioning power source for your home, is a clear example of system assembly.

Why is a Well-Defined Assembly Process Crucial?

A haphazard assembly process leads to errors, inefficiencies, and product failures. A well-defined, systematic approach is critical for ensuring quality, speed, and cost-effectiveness. This structured methodology is often seen in processes like electromechanical assembly, where every step is meticulously planned and executed. For a deeper look at a specific type of electromechanical integration, you can explore the intricacies of the box build assembly process.

The primary benefits of a robust assembly process include:

- Quality & Reliability: Ensures every unit is built to the same high standard.

- Efficiency: Streamlines workflow, reducing time and labor costs.

- Safety: Protects both the technicians performing the assembly and the end-user.

- Scalability: Allows for the consistent production of many units.

Make an Informed Decision with RenewGenius

Understanding the basics of system assembly gives you a new appreciation for the technology you invest in. When you choose a solar solution, you’re not just buying panels; you’re investing in a sophisticated system where every part must work in perfect harmony.

Our focus on residential solar solutions means we’ve perfected this assembly process to maximize performance and longevity. We leverage our comprehensive solar knowledge base to help you understand every component of your system. To see how the final assembled system translates into real-world value, our ROI calculator is the perfect tool. It helps you move beyond the technical details to make a confident financial decision for your home’s energy future.