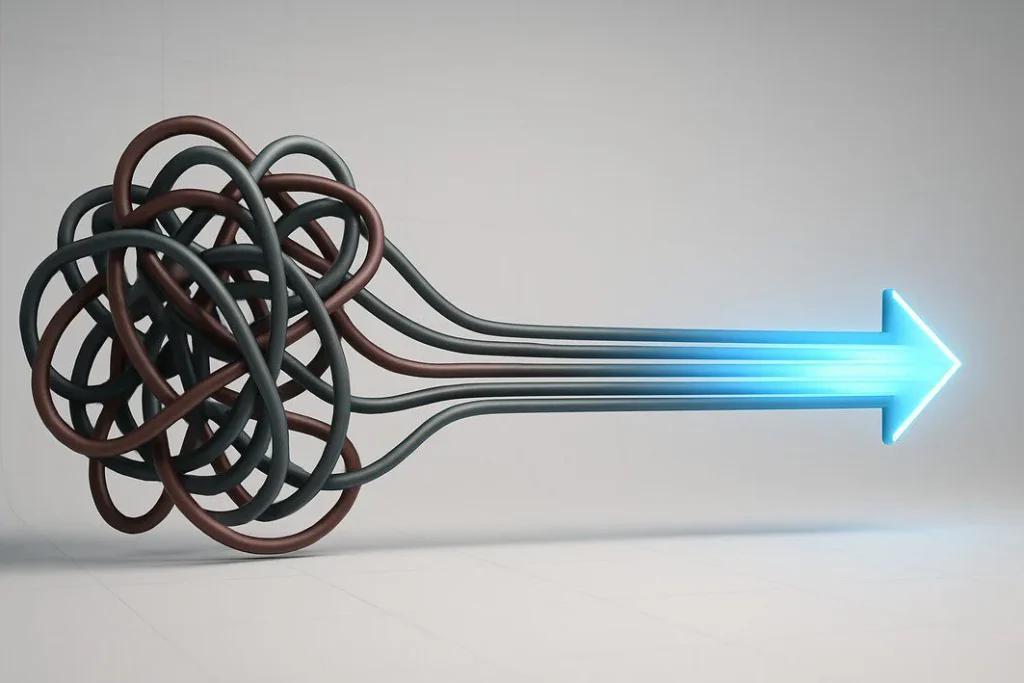

In today’s competitive landscape, managing operational expenses is more critical than ever. For professionals in manufacturing and electronics, the pressure to find effective ways to reduce supply chain costs is constant. It’s not just about cutting corners; it’s about building a more resilient, efficient, and profitable operation from the ground up. True supply chain cost optimization involves a strategic approach that examines every link in the chain, from raw material sourcing to final delivery.

Table of Contents

This guide provides actionable supply chain cost reduction strategies for 2025. We’ll explore foundational tactics and advanced technological solutions to help you trim expenses, improve cash flow, and gain a significant competitive advantage.

Understanding the Key Drivers of Supply Chain Costs

Before you can cut costs, you need to know where your money is going. The most significant expenses in any supply chain typically fall into these five categories:

- Transportation: The cost of moving goods between suppliers, manufacturing facilities, warehouses, and customers. This includes fuel, labor, freight charges, and fleet maintenance.

- Inventory Holding: The costs associated with storing unsold inventory. This includes warehousing, insurance, security, labor, and the cost of capital tied up in stock.

- Warehousing: The expenses related to operating storage facilities, including rent or mortgage, utilities, equipment, and labor.

- Procurement: The total cost of acquiring goods and materials, including the price of the components and the administrative costs of placing and managing orders.

- Reverse Logistics: The costs associated with handling returns, repairs, and recycling, which can be a significant and often overlooked drain on resources.

Foundational Supply Chain Cost Reduction Strategies

Mastering the fundamentals is the first step toward significant savings. These strategies focus on refining core processes for immediate and long-term impact.

Optimize Inventory Management

Excess inventory is a classic profit killer. It ties up capital and increases holding costs.

- Adopt a Just-in-Time (JIT) Model: Minimize inventory levels by receiving goods from suppliers only as they are needed in the production process. This requires precise forecasting and highly reliable supplier relationships.

- Improve Demand Forecasting: Use historical data and predictive analytics to more accurately forecast customer demand. Better forecasts reduce the risk of overstocking unpopular items and stockouts of high-demand products.

- Implement ABC Analysis: Categorize your inventory into A, B, and C groups. ‘A’ items are high-value products with low sales frequency, while ‘C’ items are low-value but high-frequency. This allows you to apply more rigorous inventory controls to your most valuable assets.

Streamline Transportation and Logistics

Transportation is often the largest single cost center. Even small improvements can yield big results.

- Consolidate Shipments: Whenever possible, group smaller shipments into a single, larger one (Full Truckload or FTL) to reduce per-unit shipping costs.

- Optimize Routes: Use route planning software to determine the most efficient routes for your delivery fleet, saving on fuel and driver time.

- Negotiate Carrier Contracts: Regularly review and renegotiate contracts with your shipping carriers. Building long-term relationships can lead to preferential rates and better service.

Advanced Tactics for Supply Chain Cost Optimization in 2025

Technology and strategic partnerships are the cornerstones of modern supply chain efficiency.

Leverage Technology and Automation

Investing in the right technology provides the visibility and control needed for true optimization.

- Warehouse Management Systems (WMS): A WMS optimizes warehouse operations by managing inventory tracking, order picking, and labor allocation, reducing errors and improving throughput.

- Transportation Management Systems (TMS): A TMS helps plan, execute, and optimize the physical movement of goods, providing visibility into both incoming and outgoing shipments and helping to find the most cost-effective shipping modes and carriers.

- AI and Machine Learning: Use AI-powered tools for advanced demand forecasting, predictive maintenance on equipment, and identifying hidden inefficiencies across your network.

Foster Stronger Supplier Relationships

Your suppliers are partners in your success. A collaborative relationship is far more valuable than a purely transactional one.

- Establish Long-Term Partnerships: Move away from constantly seeking the lowest-cost supplier. Long-term partnerships foster trust, reliability, and can lead to better pricing, volume discounts, and priority service.

- Collaborate on Planning: Share your production forecasts with key suppliers. This allows them to plan their own capacity more effectively, ensuring a stable supply of quality components and reducing the risk of costly disruptions.

The Role of an EMS Partner in Cost Reduction

For many electronics companies, managing a complex global supply chain in-house is a massive drain on resources and focus. Partnering with an expert Electronics Manufacturing Services (EMS) provider can be one of the most effective cost-reduction strategies of all.

An experienced EMS partner takes on the burden of procurement, logistics, and inventory management. They leverage their established supplier networks and massive purchasing power to source high-quality components at a lower cost than a single company could achieve alone. By handling everything from component sourcing and warehousing to final assembly and distribution, they allow you to focus on your core competencies: innovation and product design. An integrated partner can help you improve your supply chain and logistics services by applying proven technologies and processes to your unique challenges.

Measuring Success: KPIs for Supply Chain Cost Optimization

To ensure your strategies are working, you must track the right Key Performance Indicators (KPIs).

- Inventory Turnover: Measures how many times your inventory is sold and replaced over a period. A higher number indicates efficient inventory management.

- Cash-to-Cash Cycle Time: The time it takes to convert your investments in inventory back into cash from sales. A shorter cycle is always better.

- On-Time Delivery Rate: Tracks the percentage of orders delivered to customers by the promised date, reflecting overall supply chain efficiency.

- Total Landed Cost: Calculates the full cost of a product—including procurement, transportation, duties, and handling—giving you a true picture of profitability. Using an ROI calculator can help evaluate the financial impact of any strategic changes you implement.

By implementing these supply chain cost reduction strategies, you can build a leaner, more agile, and more profitable operation. The journey of how to reduce supply chain costs is continuous, but with a focus on data, technology, and strategic partnerships, you can position your business for sustained success in 2025 and beyond.