When designing a printed circuit board (PCB), one of the most fundamental decisions you’ll make is how to attach the components. The two dominant methods in modern electronics are Surface Mount Technology (SMT) and Through-Hole Technology (THT). Understanding the debate of surface mount technology vs through-hole technology is crucial for optimizing your product’s performance, cost, and reliability.

Table of Contents

While both methods achieve the same basic goal—creating a functional circuit—they do so in vastly different ways, each with a distinct set of advantages and disadvantages. This guide will break down the key differences in the SMT vs THT comparison to help you make an informed decision for your next PCBA manufacturing project.

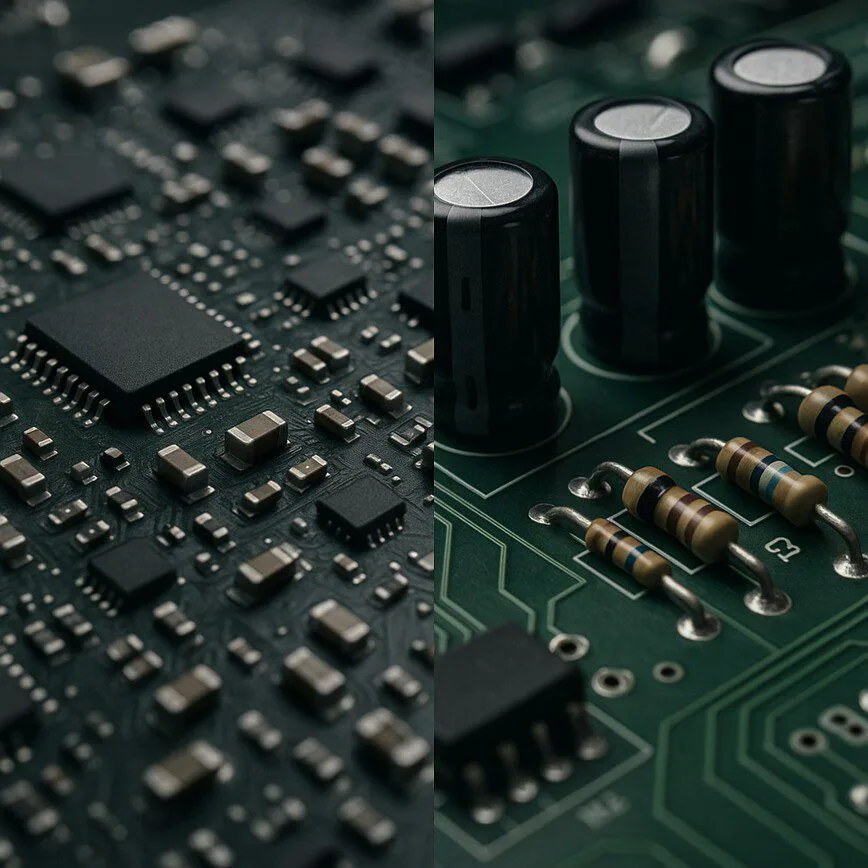

What is Surface Mount Technology (SMT)?

Surface Mount Technology is a method where electronic components, known as surface mount devices (SMDs), are mounted directly onto the surface of a PCB. Instead of using leads that pass through the board, SMDs have small metal tabs or caps that are soldered directly to pads on the board’s surface. This process is highly automated, using pick-and-place machines to position components with incredible speed and precision before the entire board is heated in a reflow oven to melt the solder.

What is Through-Hole Technology (THT)?

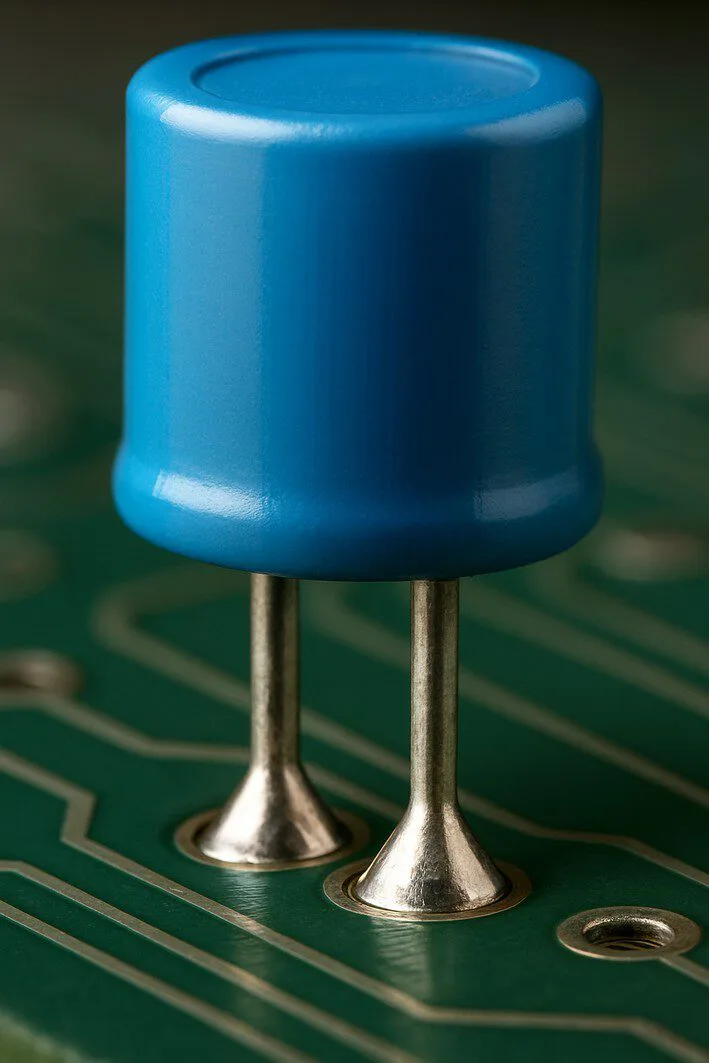

Through-Hole Technology is the more traditional method of PCB assembly. In this process, components have wire leads that are inserted through holes drilled into the PCB. These leads are then soldered to pads on the opposite side of the board, either manually or using an automated wave soldering process. This creates an exceptionally strong mechanical bond between the component and the board.

SMT vs THT: A Head-to-Head Comparison

Choosing between SMT vs through hole comes down to the specific requirements of your project. Let’s compare them across several key criteria.

Component Density and Board Size

With SMT, components can be placed much closer together, and even on both sides of the board, dramatically increasing component density. Because there are no holes to drill, SMDs are also significantly smaller. This allows for much smaller, lighter, and more compact final products.

- Winner: SMT

Assembly Process and Automation

The SMT assembly process is almost entirely automated, making it exceptionally fast and efficient for high-volume production runs. THT, while it can be automated with wave soldering, often requires manual insertion of components, which is slower and more labor-intensive.

- Winner: SMT

Cost and Efficiency

For mass production, SMT is generally more cost-effective. The high speed of automation and lower initial component costs drive down the price per board. THT’s reliance on manual labor and the need for drilling can increase costs, especially at scale. However, for small-batch prototyping, THT can sometimes be cheaper due to lower initial setup costs.

- Winner: SMT (for high-volume), THT (for some prototyping)

Durability and Mechanical Strength

This is where THT shines. The leads passing through the board create a robust physical connection that can withstand more environmental stress, vibration, and high impact. This makes THT the preferred choice for large, heavy components like transformers and connectors or for applications in harsh industrial or aerospace environments.

- Winner: THT

Performance and Signal Integrity

SMT components, with their shorter leads and direct mounting, offer superior performance for high-frequency and high-speed circuits. The shorter electrical paths reduce unwanted inductance and capacitance, leading to better signal integrity and less electromagnetic interference (EMI).

- Winner: SMT

Prototyping and Repair

THT components are larger and can be easily replaced with basic soldering tools, making THT ideal for manual prototyping, testing, and repairs. The tiny size of SMDs makes them very difficult to work with by hand, often requiring specialized hot-air rework stations.

- Winner: THT

Quick Comparison Table: SMT vs Through-Hole

| Feature | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

|---|---|---|

| Component Size | Very Small | Larger |

| Component Density | High | Low |

| Mechanical Strength | Good | Excellent |

| Automation Level | Very High | Moderate to Low |

| Production Speed | Fast | Slower |

| Best for Volume | High-Volume | Low-Volume & Prototypes |

| High-Frequency Use | Excellent | Poor to Fair |

| Repair/Prototyping | Difficult | Easy |

| Cost (High-Volume) | Lower | Higher |

When to Choose SMT vs. Through-Hole Technology

The choice isn’t always about one being better than the other, but which is right for the job.

Choose SMT if your project requires:

- A small, lightweight, or compact final product (e.g., smartphones, IoT devices).

- High component density.

- High-volume production runs where cost per unit is a key factor.

- High-frequency performance (e.g., RF applications).

Choose THT if your project requires:

- Maximum mechanical durability and resistance to stress (e.g., industrial controls, military hardware).

- The use of large, heavy, or high-power components.

- Manual prototyping or the likelihood of field repairs.

Often, the best solution is a mixed-technology board that uses SMT for the majority of small components and THT for connectors and other high-stress parts.

Making an Informed Decision with RenewGenius

Navigating the complexities of PCBA manufacturing can be challenging. The choice between SMT and THT has significant implications for your product’s final cost, size, and performance. As a company with a comprehensive solar knowledge base, we understand how critical the right component selection and assembly process are to a system’s long-term reliability and efficiency.

Our focus on residential solar solutions means we are experts at designing durable and high-performing electronics. We help our clients make informed decisions by breaking down complex technical choices into clear, actionable insights. Just as our ROI calculator helps you understand the financial benefits of solar, our expertise in electronics helps you select the most cost-effective and reliable manufacturing path for your needs. To learn more about the complete assembly journey, from component sourcing to final testing, explore our end-to-end PCBA manufacturing process.

Ultimately, the SMT vs THT debate is settled by your project’s unique goals. By understanding these key differences, you can better collaborate with your manufacturing partner to build a product that is perfectly optimized for its application.