In the world of electronics and printed circuit board (PCB) assembly, acronyms are everywhere. Two of the most fundamental, yet often confused, terms are SMT and SMD. While they sound similar and are closely related, they refer to two distinct concepts. Understanding the difference between SMD and SMT is crucial for engineers, designers, and anyone involved in electronics manufacturing.

Table of Contents

This article will clarify the smd vs smt debate once and for all. We’ll define each term, explain their relationship, and discuss why this distinction is vital for the success of your project.

What is SMT (Surface-Mount Technology)? – The Process

SMT, or Surface-Mount Technology, is a process or method used to assemble electronic circuits. In this process, electronic components are mounted directly onto the surface of a printed circuit board.

Before SMT became the industry standard, most components were assembled using the Through-Hole Technology (THT) method, where component leads were inserted into holes drilled in the PCB and then soldered on the opposite side. SMT revolutionized manufacturing by allowing for automated, high-volume production of smaller, more densely populated, and more efficient circuit boards.

The SMT process involves three main stages:

- Solder Paste Application: A stencil is used to apply solder paste precisely where the components will be placed.

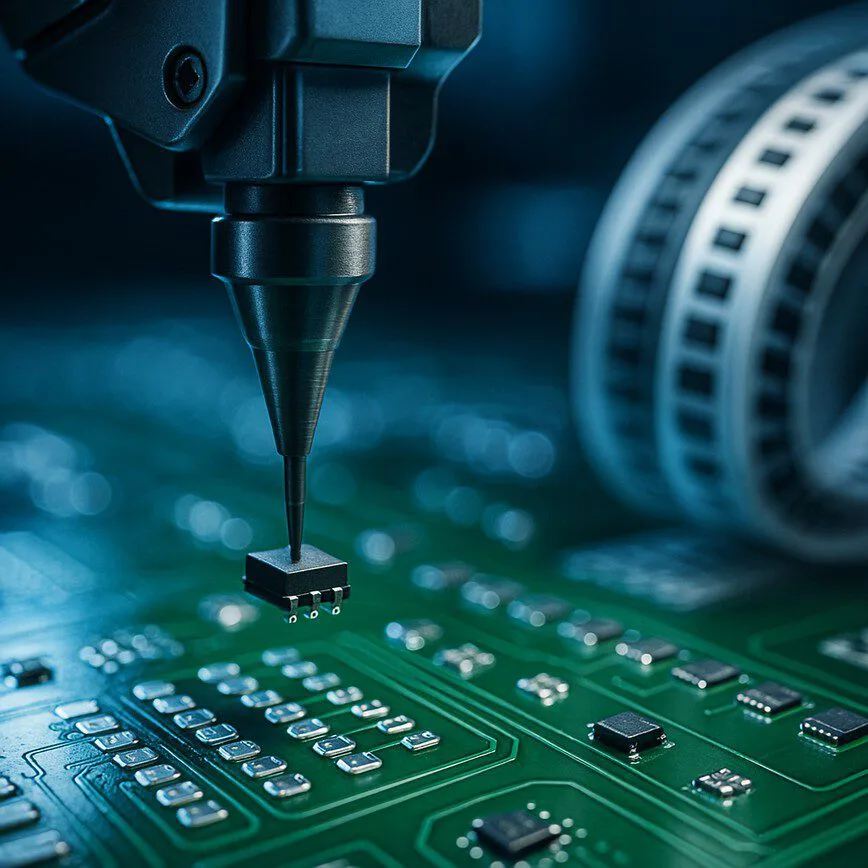

- Component Placement: Automated pick-and-place machines rapidly and accurately place the components onto the solder paste.

- Reflow Soldering: The entire board is passed through a reflow oven, which melts the solder paste to create permanent electrical connections.

What is an SMD (Surface-Mount Device)? – The Component

An SMD, or Surface-Mount Device, is the actual component that gets mounted onto the PCB using the SMT process. These components are designed specifically for surface mounting; instead of long leads meant for insertion into holes, they have small metal tabs or pads that make direct contact with the surface of the board.

When we get into SMT components explained in more detail, you’ll find that nearly every type of electronic component is available in an SMD package. Common examples include:

- Resistors and capacitors

- Transistors and diodes

- Integrated Circuits (ICs) of all types

- Connectors

These components are significantly smaller and lighter than their through-hole counterparts, which is the primary driver behind the miniaturization of modern electronics.

The Core Difference Between SMD and SMT: Component vs. Process

The easiest way to understand the core difference is with a simple analogy: SMT is the baking process, and SMDs are the ingredients.

You use the process (baking/SMT) to combine and assemble the ingredients (flour, sugar/SMDs) to create a finished product (a cake/a functional PCBA). You can’t have one without the other in this context.

Here’s a quick breakdown to resolve the smd vs smt confusion:

| Aspect | SMT (Surface-Mount Technology) | SMD (Surface-Mount Device) |

|---|---|---|

| What it is | A method, a process, a technique | A physical part, a component |

| Category | Verb / Process (“to surface-mount”) | Noun / Object (“a surface-mount part”) |

| Function | Describes how components are assembled | Describes what is being assembled |

| Example | “Our facility uses SMT for all new designs.” | “We need to order 10,000 resistor SMDs.” |

Why Does This Distinction Matter in Electronics Manufacturing?

While it may seem like a simple matter of semantics, using the correct terminology is critical for clear communication, especially when working with a contract manufacturer. When you discuss your project specifications, saying you need an “SMD board” could be confusing. Do you mean a board populated with SMDs, or are you trying to describe the assembly process?

Clarity ensures that your design intent is perfectly understood from quoting to final production. Understanding that SMT is a complex assembly method helps you appreciate the technical details involved. The specific types of SMDs you choose for your design directly influence the SMT process, affecting everything from machine programming to the thermal profile of the reflow oven.

This is just one part of a larger manufacturing ecosystem. For a deeper dive into how SMT fits within the complete assembly journey, from bare board to finished product, we recommend reading our complete overview of the PCBA manufacturing process.

Partnering with an Expert for Flawless Assembly

Navigating the technical landscape of electronics manufacturing requires precision in both language and execution. When you partner with a manufacturer, you need a team that not only understands the difference between an SMD and the SMT process but has a deep, practical mastery of how they interact.

Our comprehensive manufacturing knowledge base is built on years of hands-on experience. We help our clients make informed decisions by clarifying technical specifications and ensuring every detail of their design is optimized for flawless production. By focusing on customized PCBA solutions, we help you move from concept to reality with confidence. We provide the expertise to help you make the best decisions for your project’s budget and timeline.

By understanding the fundamentals like the difference between SMD and SMT, you are better equipped to have productive conversations and achieve a successful manufacturing outcome.