ROBOTICS AND ROBOTS

Robotics is the science that studies robots, their design, manufacture and use, and uses electronics, mechanics, engineering, and information technology to achieve its goals. For its part, a robot is a machine that can be programmed to fulfill specific tasks and can also do them autonomously.

Initially, the first robots were industrial robots, especially manipulators. In other words, they were created to carry out the toughest tasks in the industry. They could only process a few logical operations and perform repetitive motions. The objective was to be robust and durable to carry out these continuous movements.

In 1954, George Charles Devol, the father of robotics, invented the first industrial robot prototype.

Years later, in 1961, Devol and Joseph Engelberger founded the Unimation company, developing the Unimate industrial robot, which was installed in the General Motors factory for handling pressure casting and spot welding.

The evolution of technology has made robots increasingly complex, incorporating elements such as cameras or sensors for movement. Thus, primitive robot manipulators have been transformed into sophisticated artificial intelligence systems. Today, robots can perform increasingly precise and sensitive actions with unimaginable precision of movement.

WHAT ARE INDUSTRIAL ROBOTS?

Industrial robots are programmable multifunctional handling machines with the ability to move materials, parts, special devices, or tools within a production line. All this, with variable trajectories to execute task cycles or adapted according to work.

Its design is an articulated machine capable of performing movements that a human could do, but with a higher degree of effectiveness and precision in developing a task in almost any industrial process.

These can be controlled by the same qualified human operator or simply by control by means of some reprogrammable logic device.

They are composed of a structure of four fundamental parts, which are:

- The controllable and completely manipulable mechanical arm.

- Components that make up its rigid structure. The most common manufacturing part is the robotic arm. A typical robotic arm comprises seven metal segments joined by six joints.

- Joints can connect them, either rotary or linear.

- Finally, there are the “hands” of the robot, which are nothing more than tweezers or tools which serve as manipulators.

These characteristics allow the robot to adapt to any type of industry, increasing its efficiency at a lower cost of resources and greater optimization of production times.

TYPES OF INDUSTRIAL ROBOTS

Industrial robots are what we can find in many automotive and manufacturing factories.

For many years, this industrial machinery has undergone different advances and technological transformations, depending on the needs and requirements of each of the industries in which they wish to be implemented.

For this reason, there are different types of industrial robots; among this variety are:

CARTESIAN ROBOT

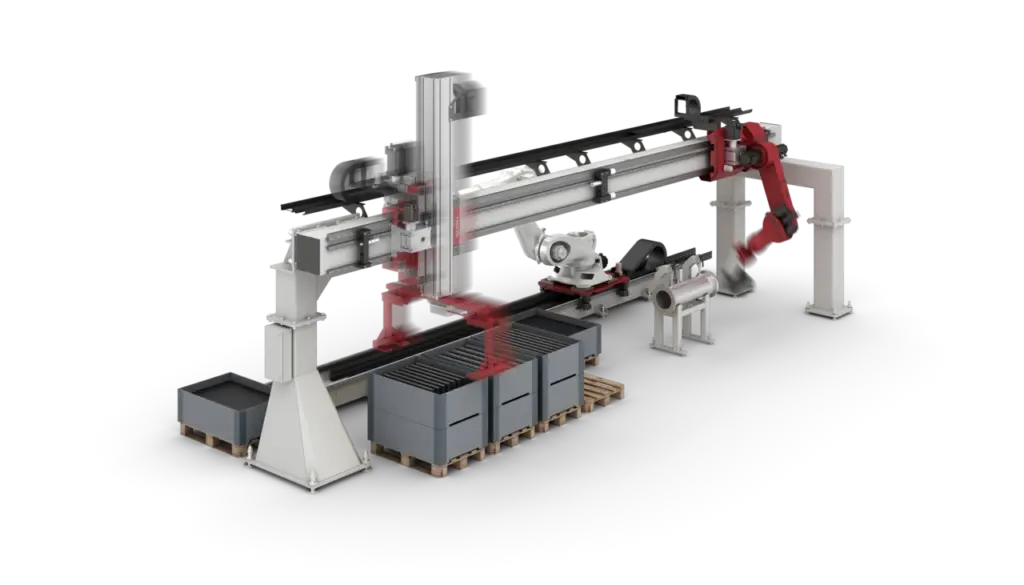

A Cartesian robot is composed of three prismatic or linear joints; therefore, the tool is limited to linear movement. The Cartesian name is derived from the three-dimensional Cartesian coordinate system, which consists of the X, Y, and Z axes.

Cartesian robots are the simplest robotic system since their operation only involves translational movements.

It is suitable for applications that only require a right-angle movement without the need to orient the load.

Also, as one or two of their prismatic joints are usually supported at both ends, they are built to carry heavier loads than other types of robots.

An example of a Cartesian robot is a gantry machine. Gantry machines, also known as gantry cranes, are used to pick and place large loads, such as palletized ones.

ANTHROPOMORPHIC OR ARTICULATED ARM ROBOT

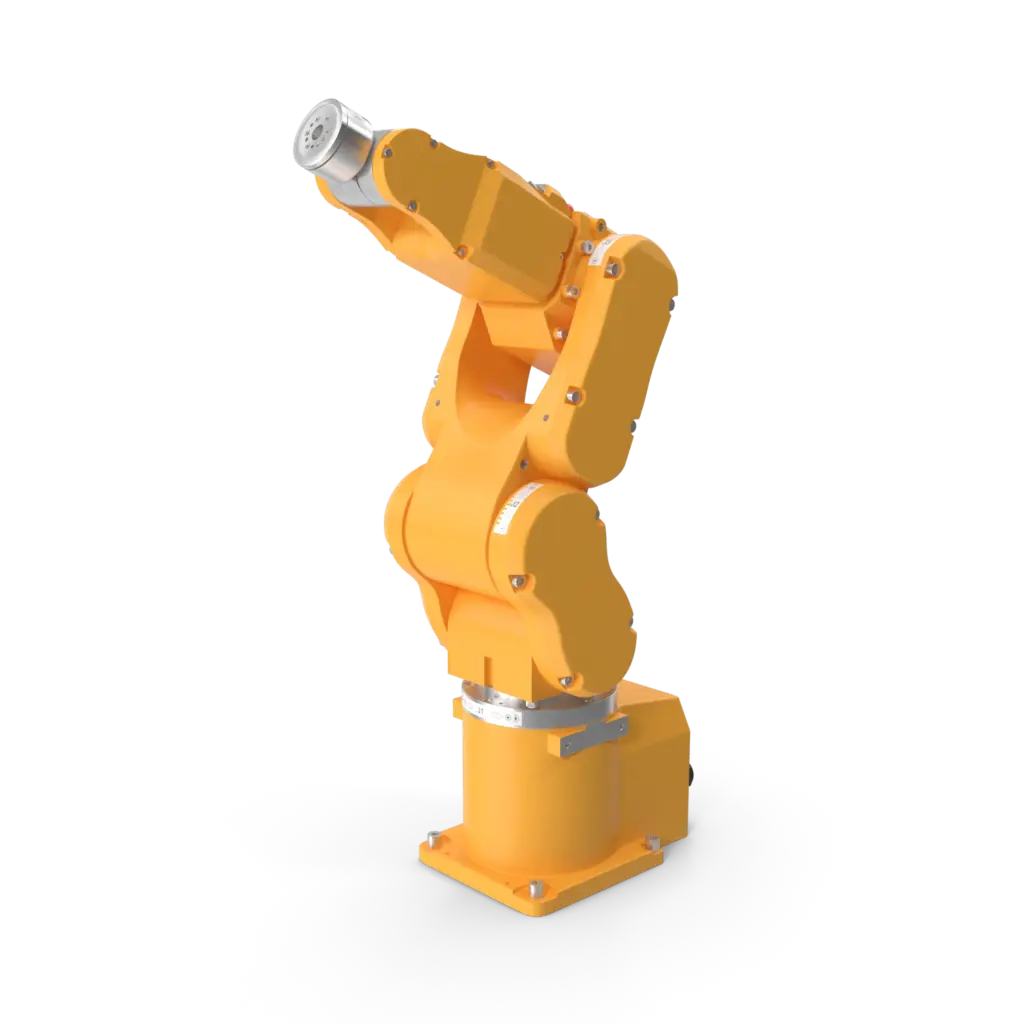

Articulated robots are the most used in manufacturing processes, and they are used to perform more complex operations such as welding, product assembly and machining.

The End Of Arm Tooling (EOAT), mounted on articulated robots, is designed to have six degrees of freedom; these are the final components of the robotic arms, which work with great efficiency and precision.

The robot arm consists of at least three pivot joints. A fourth swivel joint can be added to the wrist of the arm to rotate the EOAT.

CYLINDRICAL ROBOT

As its name suggests, a Cylindrical robot has a cylindrical range of motion. This type consists of a revolution or rotary joint and two prismatic or linear joints.

The revolution joint is located at the base of the arm and allows the rotation of the links around the axis of the robot.

The two prismatic joints are used to adjust the radius and height of the robot’s cylindrical work area.

The prismatic joint used to adjust the arm’s radius is eliminated in compact designs.

This configuration of one prismatic and one revolving joint is useful in simple pick and place operations where product feed is in one place.

SCARA ROBOT

The SCARA robot has a flexible arm in the horizontal or XY plane but rigid in the vertical direction or Z axis.

It has two links, two revolution joints and a single prismatic joint. The links and the base are connected by revolution joints oriented on the same axis.

The prismatic joint only serves to raise or lower the End Of Arm Tooling EOAT. They are often used for assembly, palletizing and biomedical applications.

DELTA ROBOT

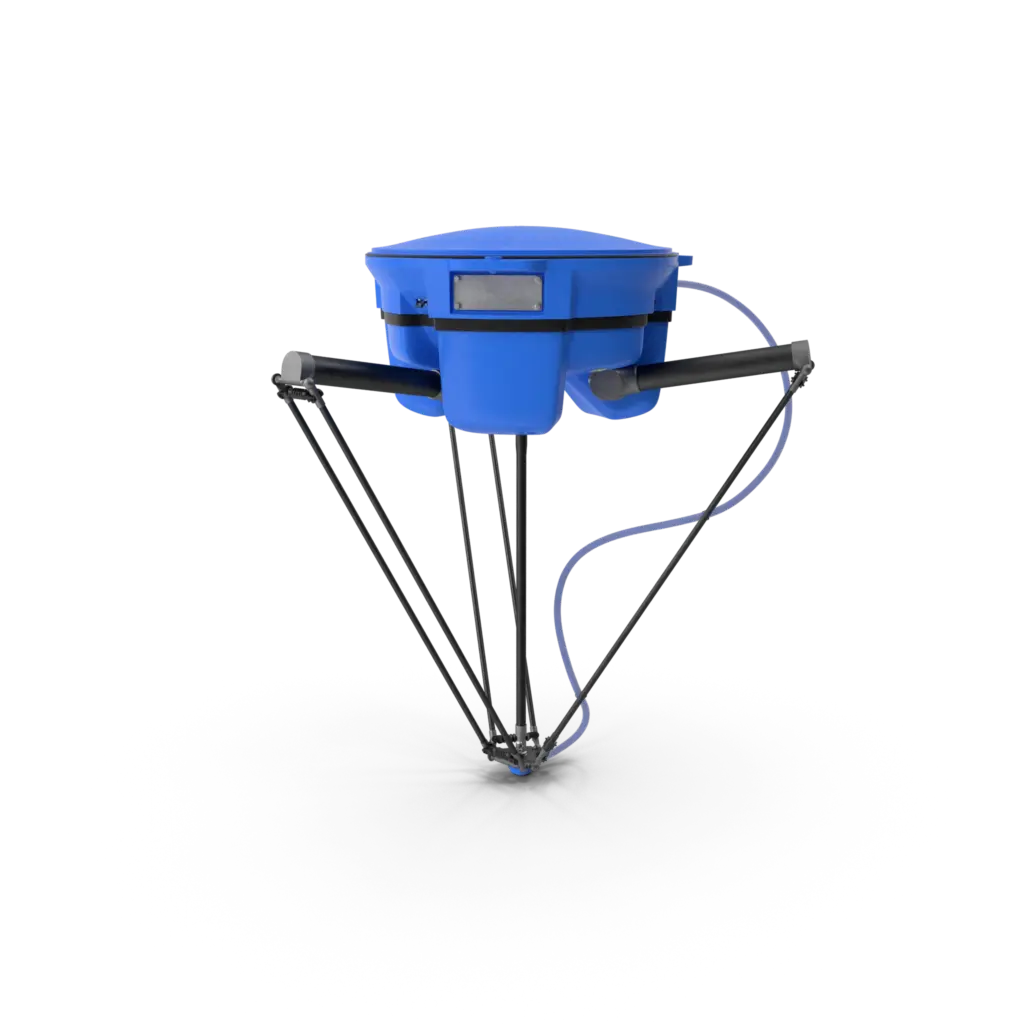

A Delta robot consists of at least three links connected to an End Of Arm Tooling, EOAT, and a common base.

The EOAT is connected to the links by three non-driven universal joints.

The base, meanwhile, is connected by three prismatic joints or three revolution-driven joints. The driven joints work together so that the EOAT has four degrees of freedom.

In designs using prismatic joints, a fourth link or shaft is often connected to the EOAT to allow for rotation.

The EOAT of a delta robot can move along all Cartesian axes and can also rotate around the vertical axis.

The result is a dome-shaped work area. Simultaneous action of all three driven joints makes delta robots suitable for quick pick and place applications in the pharmaceutical, food and electronics industries.

SPHERICAL ROBOT

Spherical robots, also known as polar robots, use the three-dimensional polar coordinate system ρ, θ, and φ.

Instead of having a rectangular prism-shaped work area, polar robots have a spherical scope.

Its range of motion has a radius equal to the length of the link connecting the EOAT and the nearest joint of revolution.

This configuration allows polar robots to have the greatest reach for a given arm’s length compared to other types of robots.

The reach of a spherical robot can be further extended by using a second link connected by a prismatic joint.

Due to their wide reach, polar robots are commonly used in machine-loading applications.

COLLABORATIVE ROBOTS VERSUS TRADITIONAL INDUSTRIAL ROBOTS

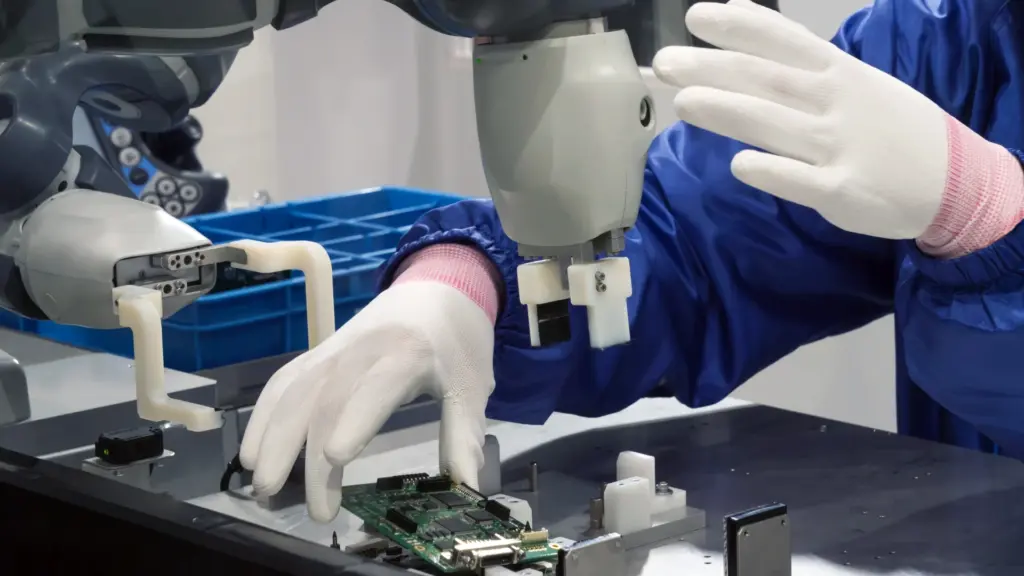

Collaborative robots and traditional industrial robots have specific uses.

Collaborative robots are designed to work safely alongside human workers in a shared workspace. In most applications, this robot is responsible for menial and repetitive tasks, for the worker to complete more complex and thought-intensive tasks.

An example of collaborative robots are cobots specifically designed to work with humans as they provide versatility, ease of use and are small in size and affordable.

On the other hand, industrial robots are machines designed and manufactured to perform tasks in dangerous or inaccessible environments, such as factories.

HOW ARE INDUSTRIAL ROBOTS USED?

Industrial robotics is used to perform highly precise and repeatable tasks that result in higher quality products. The ability of industrial robots to work continuously without rest is helping manufacturers increase production.

INDUSTRIAL ROBOTS FOR DIFFERENT APPLICATIONS

Industrial robots have multiple applications, including:

Assembly robots

The automotive industry was one of the early adopters of industrial robots for assembly.

Today, they are present in all manufacturing industries where production assembly operations need to be more efficient, especially when heavy or bulky components need to be precisely positioned, which is an exceptionally demanding task for employees.

Adhesive dispensing robots

A dispensing robot applies adhesives and sealants in a variety of applications.

These can include attaching parts to each other, placing parts in a sealant, and much more.

Smaller jobs like glue and epoxy application require a compact, high-speed robot.

Handling and picking

Robots that transport goods within a warehouse, or pick items from a container and place them in a shipping container, are examples of picking and handling robots.

With the rise of e-commerce, there is a huge and growing demand for robots that can prepare and fulfill orders.

Machine loading and feeding robots

Machine feeding robots feed parts into machines and remove them after the operation is complete.

A typical cycle is for a robotic arm to take a part from a tray, feed it into the machine, wait for the operation to complete, and then remove the finished part and place it on the same tray or perhaps another tray.

Milling robots

Milling robots allow defined cuts to be made in material from a “raw” part, shaping it into a desired part.

In this way, it allows machining metals, wood and plastics with the help of a milling tool, improving the precision and flexibility of the operation, reducing the number of defective parts and improving the safety of workers.

Drilling robots

Manual drilling is exhausting and often dangerous work. Robotic drilling offers more precision and repeatability than manual drilling. Performance increases and workers are freed up to focus on more rewarding work.

Milling and drilling are similar in that they both involve EOATs designed to remove material from a workpiece by rotating and cutting.

For this reason, the two operations are sometimes combined in a single robot. The robot arm can automatically change tools to alternate between milling and drilling.

Laser cutting robots

Laser cutting represents a superior solution to mechanical cutting. It offers less possibility of material deformation and greater precision because the laser beam that performs the cut is not dented with use.

Welding robots

These robots perform welding, a process in which elements are joined by putting a molten filler material (solder) into the joint.

Some examples of the use of welding are copper pipes in plumbing, as well as electronics, jewelry, and medical instruments.

Robotic welding stations range from the smallest, bench-top, for relatively low production volumes, to large systems handling very high production rates.

Die Casting Robots

Die casting is ideal for simultaneously manufacturing many different and intricate part designs. However, it does not usually involve the creation of large parts.

Materials with a high melting point, such as steel, are unsuitable for die casting. Typical materials are zinc, copper and magnesium.

Robotic arms can automate the removal of the part from the die, the placement of the part in a cooling bath, the removal of excess material, and its placement onto a transport system.

When the pieces come out of the die, they are very hot and are usually cooled by being placed in water.

These processes expose operators to danger. Using robots to perform these operations is safer and less tiring for operators.

Painting and coating

Industrial painting and coating is the process of applying paint or other coatings to a part.

In manufacturing, the part to be painted or coated is well defined in terms of shape and size, making painting and coating operations highly repetitive and ideal for robotic automation.

The results are consistent and high quality and the machines can work continuously without pauses or downtime.

By using robotics, workers do not have to be exposed to harmful fumes or overspray, and safety is improved.

Packing and palletizing

Packing and palletizing are two operations common to manufacturing, warehouses, and distribution centers.

As the trend towards smaller packages continues, the repetitive nature of packaging and palletizing operations is increasing, a function where the implementation of robotics enables increased productivity.

INDUSTRIAL ROBOTS FOR SMARTER AUTOMATION

More intelligent autonomous systems are generated by combining robotics with Artificial Intelligence.

Artificial Intelligence (AI) is the combination of algorithms proposed to create machines with the same capabilities as human beings.

Thus, with machine learning, image recognition, cognitive services and more, robots can learn and respond to requirements that go beyond simple commands.

ROBOTS SUPPORT DIGITAL AUTOMATION.

With a robot’s ability to share tasks and learn through AI, companies can more easily adopt intelligent automation in new environments, from construction to food and beverage packaging facilities to healthcare labs.

BENEFITS

Lorem ipsum dolor sit amet, Robotic process automation allows any industrial company to increase its productivity, efficiency, and competitiveness regardless of the sector to which it belongs and the process it develops.

Scalability

Robotics allows the organization to scale its operations and transaction volumes without increasing its human workforce. This scale can be achieved in minutes instead of months, significantly less time than it takes to recruit and train a human team.

Quality

Once implemented correctly and with accurate data to work with, a Robot is 100% accurate and delivers perfect quality every time. Robots are not prone to errors in transcribing a data set. Also, they are forced to obey the business logic of any target application so they don’t interfere with a provider’s logic or databases.

Agility

Having a pool of “digital workforce” means that an organization can create new processes very quickly, in days and weeks rather than months, leveraging existing systems rather than acquiring new ones and additional staff.

CONCLUSION

It is evident that technology has drastically changed how robots are made and operated. Robots are becoming more complex and realistic with new advancements, making them a firm part of industrial production. It is important to note that with the improvement of technology comes the potential for even greater progress in the future.