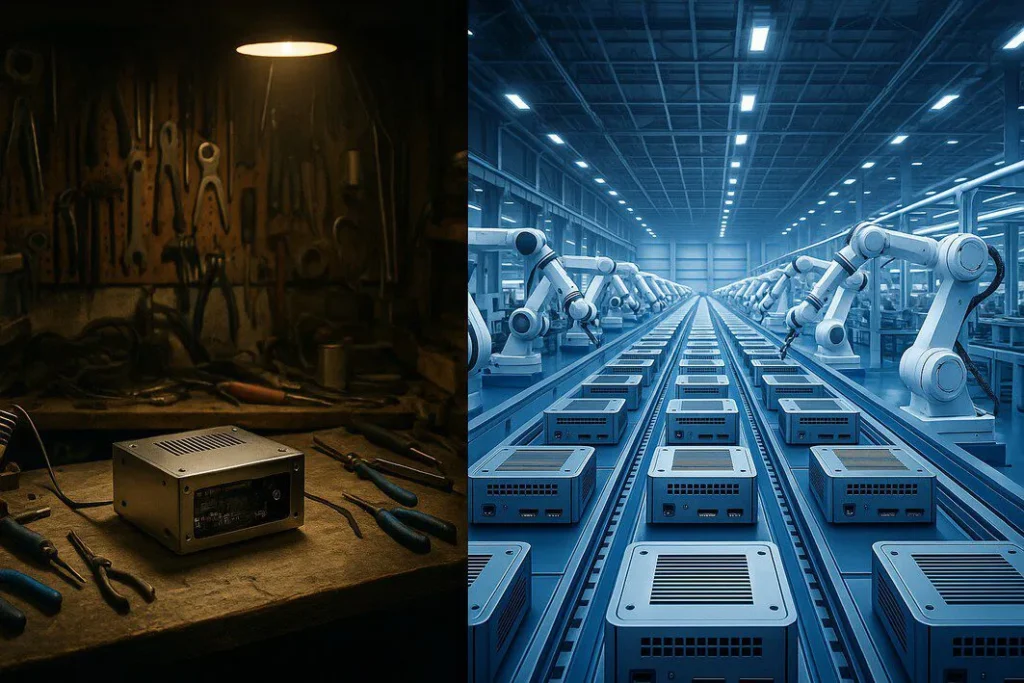

Bringing a new product to life is a complex journey, from initial concept and design to engineering, marketing, and sales. One of the most critical decisions a company faces is how to actually build it. While in-house production offers control, it often comes with staggering costs, logistical headaches, and a steep learning curve. This leads many business leaders to ask: why might a company choose contract manufacturing?

Table of Contents

The answer lies in strategic partnership. By leveraging the expertise of a specialized manufacturing partner, businesses can unlock significant advantages that fuel growth and innovation. For those just beginning to explore this model, understanding the fundamentals of contract manufacturing is the first step toward making a confident, informed decision.

Here are the seven key business benefits and primary reasons to outsource manufacturing.

1. Significant Cost Savings

One of the most compelling pros of outsourcing is the immediate and substantial reduction in costs. Establishing an in-house manufacturing facility requires immense capital expenditure for equipment, infrastructure, and technology. A contract manufacturer (CM) has already made these investments.

By partnering with a CM, you eliminate these upfront costs and benefit from their economies of scale. They can source raw materials at a lower cost due to bulk purchasing and have optimized production processes that reduce waste and labor expenses, translating directly to a lower cost-per-unit for your product.

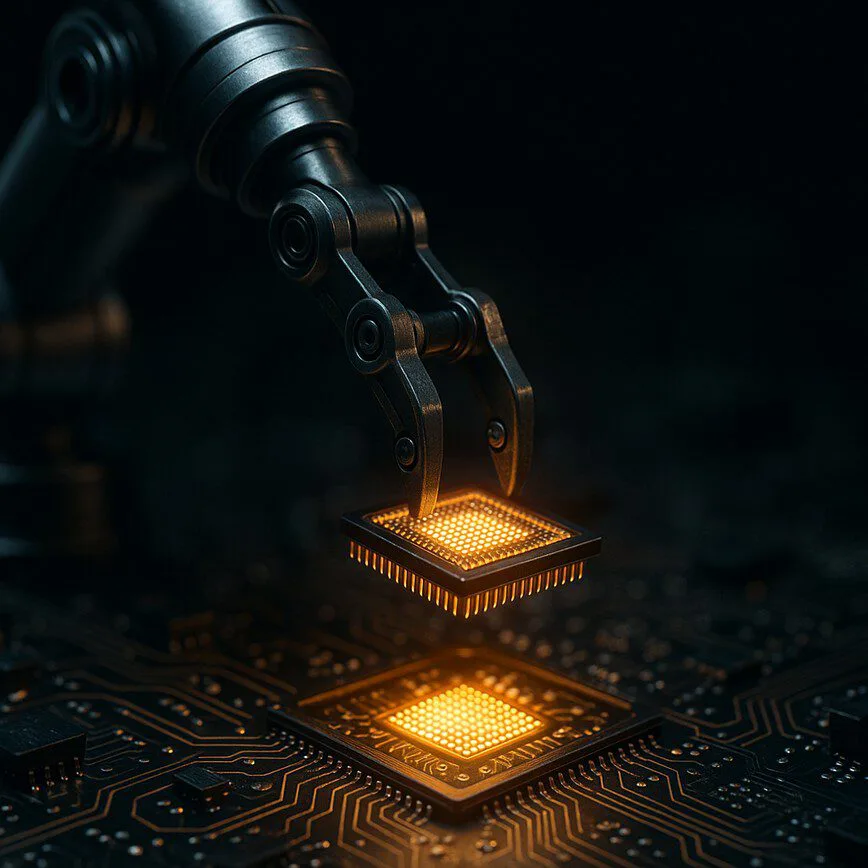

2. Access to Specialized Expertise and Technology

Contract manufacturers are specialists. They live and breathe production, and their teams possess deep domain knowledge, from process engineering to supply chain management. This is especially critical in complex fields like electronics. Gaining the benefits of outsourcing electronic manufacturing services means you instantly gain access to a team of experts and state-of-the-art equipment that would be prohibitively expensive to build internally.

This specialized knowledge ensures your product is built using the latest techniques and technologies, often resulting in a superior final product that is more reliable and efficient to produce.

3. Enhanced Scalability and Flexibility

Market demand is rarely static. It ebbs and flows with seasonality, market trends, and the success of your launch. A contract manufacturer provides the agility to scale production up or down in response to real-time demand.

Need to ramp up for a holiday rush? Your CM can add shifts and dedicate more line time. Is demand slower than anticipated? You can scale back without the financial burden of idle facilities or the difficult decision of laying off skilled workers. This flexibility allows you to be more responsive to the market without taking on unnecessary risk.

4. Improved Product Quality and Consistency

Reputable contract manufacturers build their business on a foundation of quality. They rely on robust, documented quality management systems (like ISO 9001 certification), rigorous testing protocols, and highly trained technicians to ensure every unit meets exact specifications.

This focus on process control and quality assurance often leads to higher consistency and fewer defects than a company could achieve when first setting up its own production line. The CM’s experience in spotting potential issues early in the process prevents costly errors and ensures a reliable product reaches your customers.

5. Faster Time-to-Market

In today’s competitive landscape, speed is a crucial advantage. Setting up a new manufacturing line can take months or even years. A contract manufacturer has an established, proven infrastructure ready to go.

By leveraging their existing processes, supply chains, and skilled workforce, you can drastically shorten the timeline from final design to finished product. This allows you to launch faster, capitalize on market opportunities, and begin generating revenue sooner.

6. Reduced Risk and Compliance Burden

Manufacturing is fraught with risks, from supply chain disruptions and labor shortages to regulatory compliance and workplace safety. When you partner with a CM, you transfer a significant portion of this risk.

An experienced CM is adept at navigating global supply chains, managing inventory, and ensuring the facility and processes comply with all relevant industry standards and government regulations. This frees your team from a heavy administrative and compliance burden, mitigating potential liabilities and unforeseen disruptions.

7. Sharpened Focus on Core Business Functions

Perhaps the most strategic of all reasons to outsource manufacturing is the freedom it gives you to focus on what your business does best. Your internal resources—time, talent, and capital—are finite. By entrusting production to an expert partner, you can redirect those resources toward your core competencies.

Instead of managing factory logistics, your team can concentrate on:

- Research and development (R&D)

- Product innovation and design

- Marketing and brand building

- Sales and customer relationships

This sharpened focus accelerates innovation and strengthens your competitive position in the market, making outsourcing a powerful engine for strategic growth.