Scaling your business from a great idea to a market-ready product presents a significant challenge: production. How do you manufacture high-quality goods efficiently without investing in expensive facilities and specialized staff? For countless companies, the answer is contract manufacturing. But what is contract manufacturing, exactly? In simple terms, it’s a strategic partnership where a company outsources its production processes to a specialized third-party manufacturer.

Table of Contents

This guide will serve as your definitive resource, exploring the core concepts of this powerful business model. We’ll break down how does contract manufacturing work, uncover its key benefits, and help you determine if it’s the right move for your business. By understanding this process, you can make an informed decision with confidence and unlock new potential for growth.

What is the Meaning of Contract Manufacturing? A Clear Definition

At its core, the meaning of contract manufacturing defines a business relationship where a hiring firm, often called an Original Equipment Manufacturer (OEM), contracts with another firm—the contract manufacturer (CM)—to produce components or final products based on the OEM’s designs and specifications.

Think of it like this: you have a unique recipe for a gourmet sauce (your product design), but you don’t own a bottling plant (your factory). You partner with a specialized food production facility that has all the equipment, safety certifications, and expertise to produce, bottle, and package your sauce at scale. You maintain ownership of your recipe and brand, while they handle the complexities of production. This is the essence of contract manufacturing.

How Does Contract Manufacturing Work? The Step-by-Step Process

The journey from a design file to a finished product is a structured process. While specifics can vary, the workflow generally follows these key stages.

Step 1: Initial Consultation and Design Review

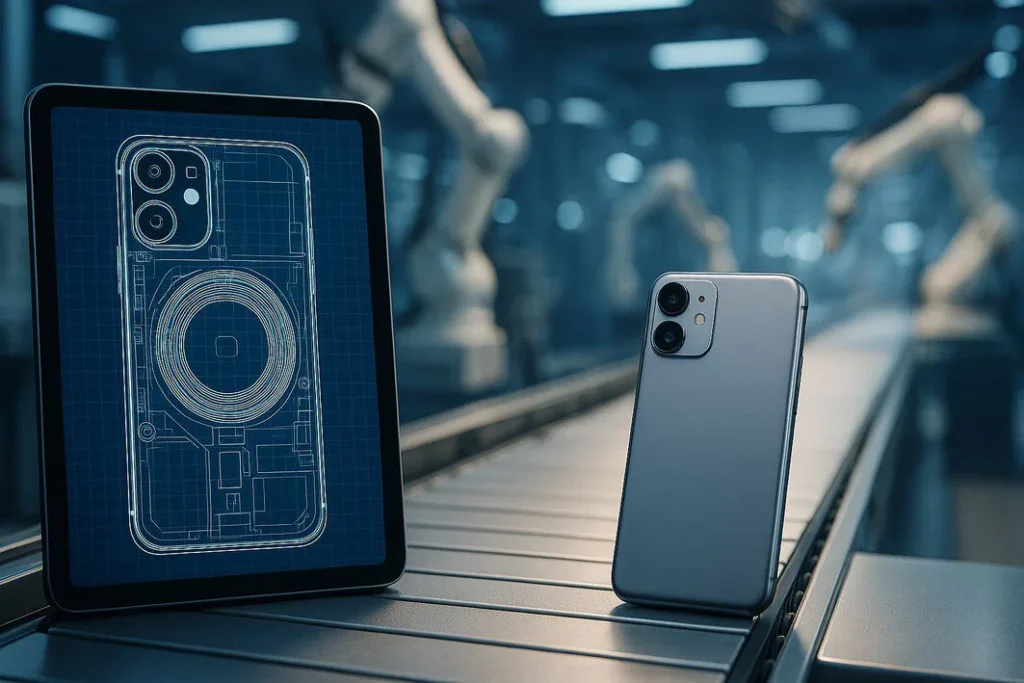

It all begins with your idea. You approach a potential contract manufacturer with your product designs, specifications, and requirements. The CM’s engineering team will review these plans for feasibility, offering feedback on materials, potential production challenges, and opportunities for cost optimization. This collaborative stage leverages the CM’s comprehensive knowledge base to refine the design for manufacturing (DFM).

Step 2: Quoting and Agreement

Once the design is finalized, the contract manufacturer provides a detailed quote. This typically includes the cost per unit, tooling costs, setup fees, and estimated lead times. A good partner will be transparent about all costs, helping you understand the potential return on investment (ROI). If the terms are agreeable, both parties sign a formal contract that outlines all responsibilities, quality standards, and intellectual property protections.

Step 3: Prototyping and Testing

Before committing to a full production run, the CM produces a small batch of prototypes or a “first article.” This allows you to inspect the physical product, test its functionality, and verify that it meets every specification. Any necessary adjustments are made during this critical phase to ensure the final product is perfect.

Step 4: Full-Scale Production and Assembly

With an approved prototype, full-scale production begins. The contract manufacturer procures the raw materials, sets up the assembly lines, and manufactures your product in the agreed-upon quantity. Their expertise in managing supply chains and production workflows is a primary advantage of this model.

Step 5: Quality Control and Shipping

Throughout the production process, and especially upon completion, rigorous quality assurance (QA) checks are performed. These tests ensure that every unit meets the standards defined in the contract. Once the batch passes inspection, the products are packaged and shipped to your warehouse or directly to your distributors.

Key Benefits of Partnering with a Contract Manufacturer

Why do so many companies choose to outsource production? The advantages are significant and impact nearly every aspect of the business.

Cost Savings and Financial Efficiency

Building, equipping, and staffing a manufacturing facility requires enormous capital investment. Contract manufacturing converts these fixed costs into variable costs, allowing you to pay only for what you produce. This model helps you save on labor, equipment, and overhead, making it a financially efficient strategy for growth.

Access to Specialized Expertise and Technology

Top contract manufacturers possess state-of-the-art equipment and a team of experts dedicated to production. This gives you access to advanced technology and deep manufacturing expertise that would be difficult and expensive to develop in-house.

Increased Scalability and Flexibility

Need to ramp up production to meet a sudden surge in demand? Or scale back during a slow season? A contract manufacturer provides the flexibility to adjust production volumes without the headaches of hiring or laying off staff. This agility is a powerful competitive advantage.

Enhanced Focus on Core Business Functions

By outsourcing production, you free up your internal team to focus on what they do best: research and development, marketing, sales, and brand building. This sharpens your company’s focus and accelerates growth in other critical areas.

Is Contract Manufacturing Right for Your Business?

Contract manufacturing is an incredibly powerful tool, but it’s most effective in certain scenarios. It is an ideal solution for:

- Startups and Entrepreneurs: Launch a physical product without the prohibitive upfront cost of a factory.

- Growing Businesses: Scale production quickly to meet rising customer demand without taking on massive financial risk.

- Companies Entering New Markets: Test a new product line or geographic market with minimal investment.

- Businesses with Seasonal Demand: Flexibly manage production peaks and troughs without carrying the cost of idle capacity.

Making the leap to outsourcing requires a clear understanding of its strategic role. To fully grasp the strategic advantages, it’s helpful to explore a comprehensive overview of contract manufacturing and how it has evolved to become a cornerstone of modern industry.

Choosing the Right Partner: What to Look For

Your contract manufacturer is more than a vendor; they are a strategic partner. When evaluating potential CMs, look for:

- Industry Experience: Do they have a proven track record in your industry or with similar products?

- Quality Certifications: Do they hold relevant certifications (like ISO 9001) that demonstrate a commitment to quality?

- Technical Capabilities: Do they have the right equipment and technical expertise to meet your specific design needs?

- Transparency and Communication: A great partner communicates clearly, provides regular updates, and is transparent about costs and timelines, helping you fully understand your investment.

By choosing a partner who aligns with your goals and values, you are not just outsourcing production—you are building a foundation for sustainable, long-term success.

“