Navigating the world of outsourcing can be complex, but finding the right partner is a critical step toward scaling your operations and bringing your product to market efficiently. This guide is designed to demystify contract manufacturing services, providing a clear roadmap for selecting a partner that aligns with your technical needs, budget, and long-term goals. Whether you are a startup launching your first product or an established company looking to optimize your supply chain, understanding how to evaluate and choose a provider is paramount.

Table of Contents

The right partnership goes beyond simple production; it involves collaboration, expertise, and a shared commitment to quality. Let’s explore the key considerations for finding the perfect fit for your project.

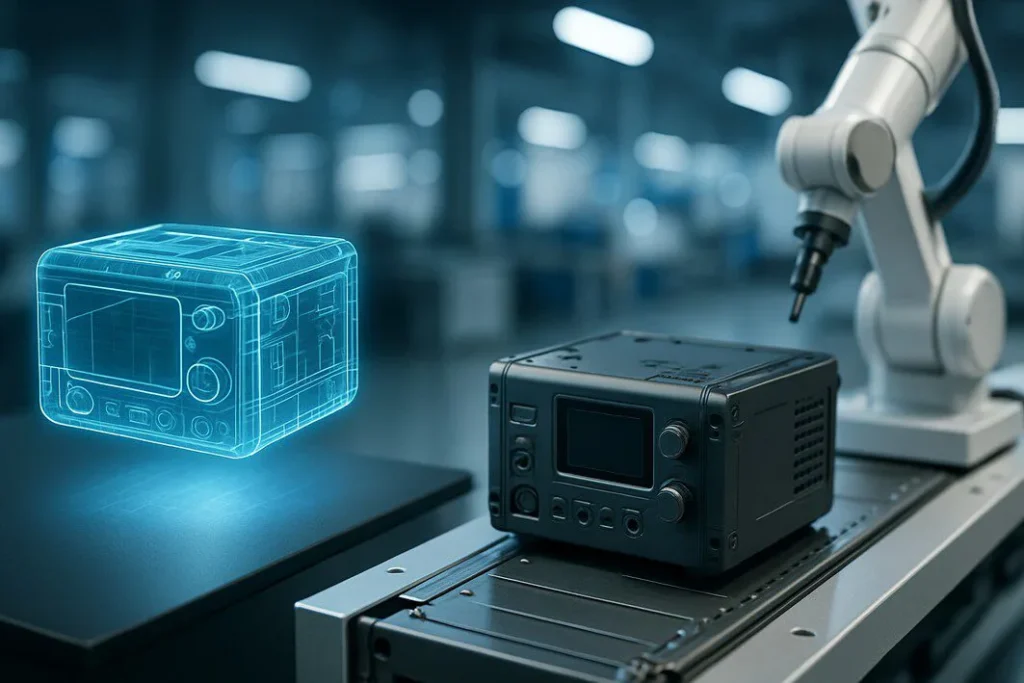

What Are Contract Manufacturing Services?

At its core, contract manufacturing services involve partnering with a specialized company to handle all or part of your product’s manufacturing process. This can include:

- Initial prototyping and design for manufacturability (DFM) analysis

- Full-scale production and assembly

- Component sourcing and supply chain management

- Quality assurance testing

- Final packaging and shipping

This strategic outsourcing allows your business to focus on its core competencies, such as research and development, marketing, and sales, while relying on a professional team to manage the complexities of production. For a deeper dive into the foundational principles, it’s helpful to start by understanding the fundamentals of contract manufacturing.

Key Benefits of Partnering with a Contract Manufacturer

Engaging a contract manufacturer offers significant strategic advantages that can directly impact your bottom line and market agility.

- Cost Efficiency: Avoid the substantial capital expenditure required for manufacturing facilities, advanced equipment, and skilled personnel. Contract manufacturers achieve economies of scale by serving multiple clients, resulting in lower per-unit costs for you.

- Access to Expertise: Top-tier manufacturers bring a wealth of specialized knowledge to the table. From materials sourcing to process optimization and regulatory compliance, their experience helps you avoid common pitfalls and build a better product. Our comprehensive knowledge base ensures we can tackle even the most complex manufacturing challenges.

- Enhanced Scalability: Seamlessly scale your production up or down in response to market demand without the risks associated with managing your own workforce and facility capacity.

- Focus on Core Business: Free up your internal resources to concentrate on what you do best—innovating, designing, and growing your brand.

- Risk Mitigation: A reliable partner helps manage supply chain risks, quality control, and production timelines, providing greater predictability for your business operations.

How to Choose the Right Contract Manufacturing Partner

The selection process is the most critical stage. A methodical approach will help you identify a partner that is truly aligned with your needs.

Define Your Project Requirements

Before you begin your search, clearly document your project’s scope. This includes:

- Detailed product specifications and CAD files.

- Estimated production volumes (initial and long-term).

- Bill of Materials (BOM).

- Quality standards and required certifications (e.g., ISO 9001, AS9100).

- Budget and target cost-per-unit.

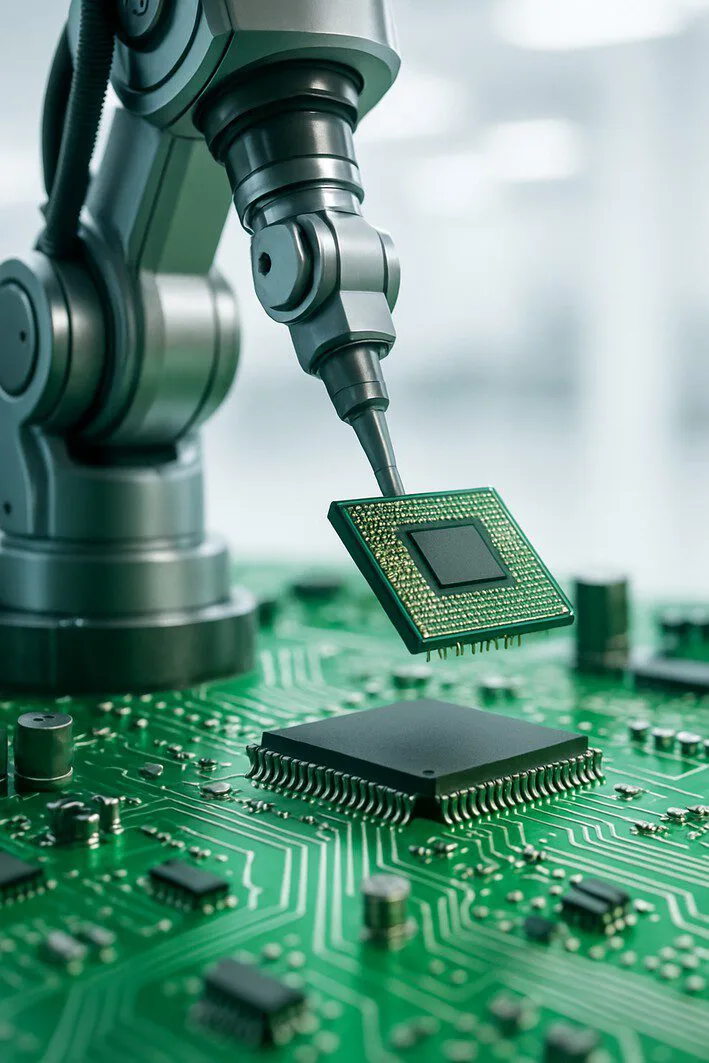

Evaluate Technical Capabilities

Assess whether the potential partner has the right equipment, technology, and engineering expertise for your specific product. Ask for case studies or examples of similar projects they have completed. Do they offer turnkey solutions, from sourcing components to final assembly and testing?

Assess Quality Control and Communication

A robust quality management system is non-negotiable. Inquire about their inspection processes, testing protocols, and how they handle defects. Furthermore, clear and consistent communication is the bedrock of a successful partnership. Who will be your dedicated point of contact? How often will you receive progress updates?

Consider Location: The “Contract Manufacturing Companies Near Me” Factor

Searching for “contract manufacturing companies near me” has distinct advantages. A local or domestic partner can offer easier site visits, more collaborative engineering sessions, faster shipping times, and alignment on regulatory standards. While overseas manufacturing can sometimes offer lower costs, it’s crucial to weigh those savings against potential challenges in communication, logistics, and intellectual property protection.

The Importance of Effective Contract Negotiation

Once you’ve shortlisted potential partners, the contract negotiation phase begins. This legal agreement will govern your entire relationship, so it requires careful attention to detail. Key areas to focus on include:

- Intellectual Property (IP): Clearly define who owns the design IP and any process improvements made during manufacturing.

- Pricing and Payment Terms: Lock in unit pricing, payment schedules, and terms for tooling or non-recurring engineering (NRE) costs.

- Quality & Testing: Specify the acceptable quality level (AQL), warranty terms, and procedures for handling non-conforming parts.

- Lead Times & Delivery: Establish firm timelines for production runs and delivery schedules.

- Liability & Indemnification: Clearly outline each party’s responsibilities in case of product failure, recalls, or other issues.

Why Choose Our Contract Manufacturing Services?

Choosing a partner is about more than just capabilities; it’s about trust and transparency. We pride ourselves on providing comprehensive contract manufacturing services that act as an extension of your team. Our focus on residential and commercial solutions is backed by a robust framework that ensures quality and reliability.

With our deep engineering expertise and commitment to proactive communication, we help you navigate every stage of the manufacturing lifecycle. Our transparent quoting process and DFM analysis provide you with the insights needed to make informed decisions, ensuring your project is optimized for success from day one.

Ready to bring your product to life with a reliable manufacturing partner? Contact us today to discuss your project requirements and discover how our services can help you achieve your goals.