In the world of manufacturing, one of the most fundamental decisions a business must make revolves around its assembly process. The choice between automated vs manual assembly equipment is not just a technical one; it’s a strategic decision that impacts everything from production speed and quality to long-term profitability and scalability. As consumers become more interested in the lifecycle of the products they buy—from complex electronics to residential solar systems—understanding the manufacturing backbone becomes increasingly relevant.

Table of Contents

This comparative analysis will break down the core differences, benefits, and drawbacks of both manual and automated approaches. Our goal is to provide the insights needed to make an informed decision with confidence, a principle we champion at RenewGenius through our comprehensive solar knowledge base. Whether you’re scaling a production line or simply curious about how modern products are made, this guide will clarify the key considerations.

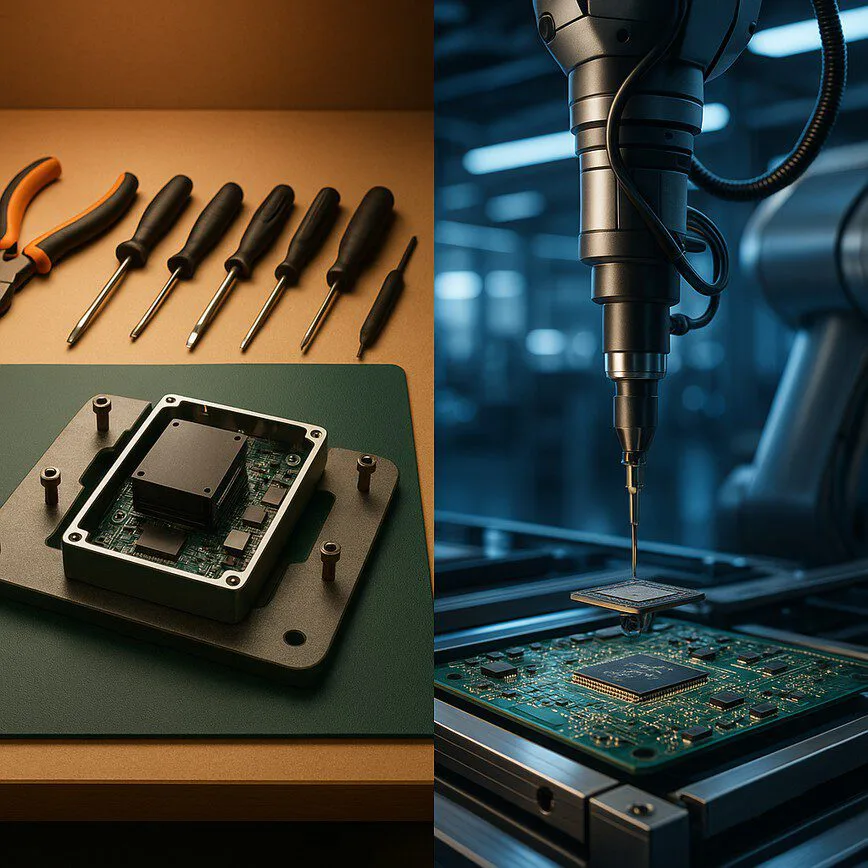

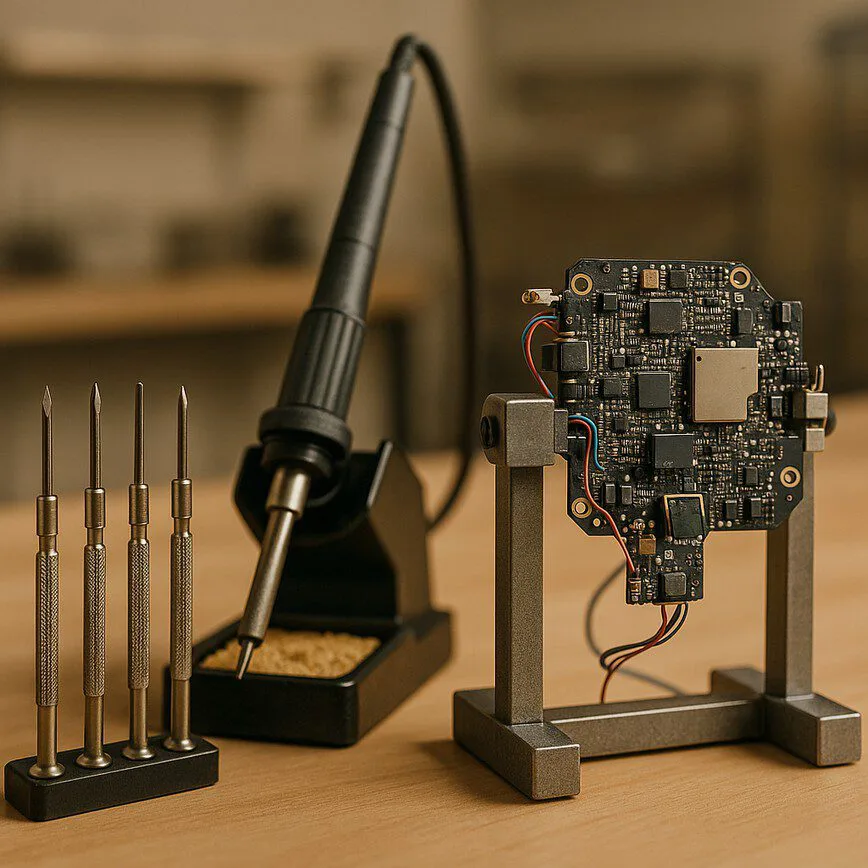

What is Manual Assembly Equipment?

Manual assembly equipment refers to the tools, workstations, and jigs used by human operators to build products. In this setup, the skill, dexterity, and cognitive ability of the technician are central to the process. Assembly can range from simple hand tools like screwdrivers and soldering irons to more advanced pneumatic tools and ergonomic workstations designed to improve efficiency and reduce fatigue.

Advantages of Manual Assembly:

- Flexibility: Human operators can easily switch between tasks and adapt to changes in product design or custom orders with minimal downtime.

- Low Initial Investment: The upfront cost for setting up a manual assembly line is significantly lower than an automated one, making it accessible for startups and small-batch production.

- Ideal for Complexity: For products with intricate, non-uniform steps that require fine motor skills and problem-solving, manual assembly is often superior.

Disadvantages of Manual Assembly:

- Slower Production Speed: Manual processes are inherently slower than automated ones, limiting throughput.

- Inconsistent Quality: The potential for human error can lead to variations in quality from one unit to the next.

- Higher Long-Term Labor Costs: While the initial investment is low, ongoing labor costs can become a significant expense, especially as production scales.

- Ergonomic and Safety Risks: Repetitive tasks can lead to worker fatigue and musculoskeletal injuries if not properly managed.

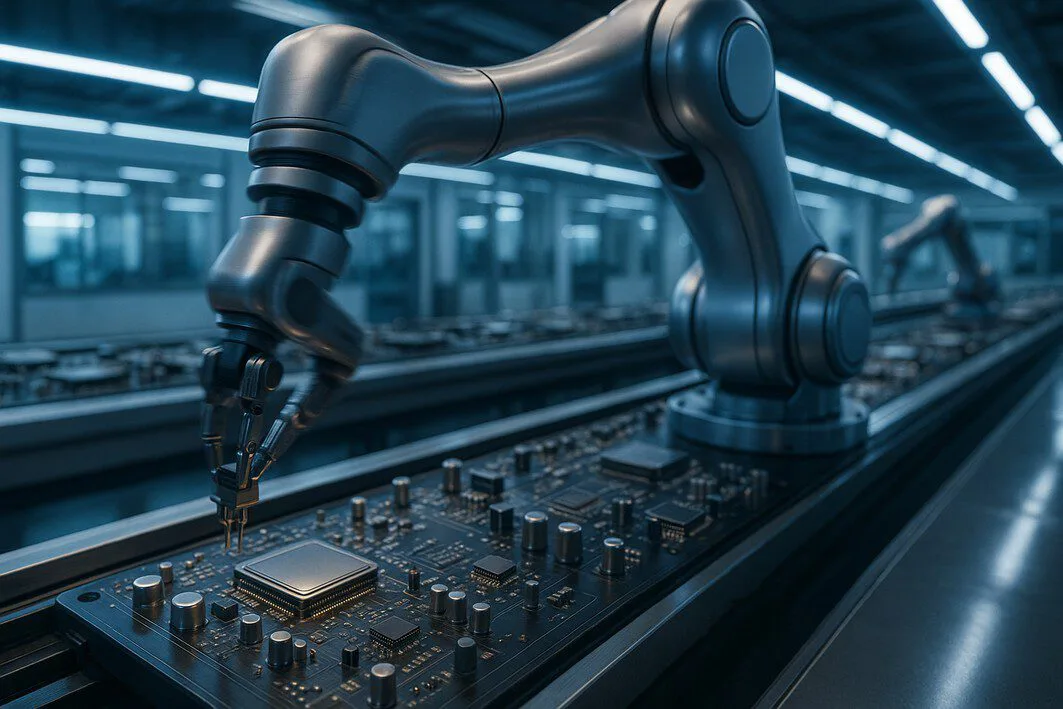

What are Automated Assembly Systems?

Automated assembly systems utilize robotics, custom machinery, computer software, and sensors to perform assembly tasks with little to no human intervention. These systems can range from single-station robotic cells to massive, fully integrated production lines where components are moved, placed, fastened, and tested automatically.

Advantages of Automated Assembly:

- High Speed and Throughput: Automation enables 24/7 operation at a pace far exceeding human capability, making it perfect for mass production.

- Superior Consistency and Precision: Machines perform the same task with the exact same precision every time, dramatically improving product quality and reducing defect rates.

- Lower Operating Costs: After the initial investment, automation reduces per-unit costs by minimizing labor and increasing efficiency.

- Enhanced Safety: Robots can take over dangerous, strenuous, or highly repetitive tasks, creating a safer work environment for human employees.

Disadvantages of Automated Assembly:

- High Initial Capital Investment: The cost of designing, building, and implementing an automated system is substantial.

- Lack of Flexibility: Reconfiguring an automated line for a new product design can be complex, time-consuming, and expensive.

- Maintenance Requirements: These systems require specialized technicians for maintenance, programming, and troubleshooting.

Key Factors for Comparison: Automated vs Manual Assembly Equipment

Choosing the right path requires a careful analysis of your specific needs. Here are the critical factors to weigh when comparing automated vs manual assembly equipment.

Production Volume and Speed

This is often the primary deciding factor. For low-volume, high-mix production or prototyping, the flexibility of manual assembly is unmatched. For high-volume, low-mix mass production where speed is critical, automated assembly systems are the only viable option.

Cost Analysis: Initial Investment vs. Long-Term ROI

Manual assembly offers a low barrier to entry, but automated systems deliver a stronger long-term return on investment (ROI) for high-volume operations. This mirrors decisions consumers make, such as investing in a solar system. Just as our ROI calculator helps homeowners understand the long-term savings of solar, businesses must calculate the payback period for automation through reduced labor costs and increased throughput.

Quality, Consistency, and Precision

If your product requires extremely tight tolerances and near-perfect consistency, automation is the clear winner. The benefits of automated assembly shine brightest in quality control, where machine precision eliminates the variability inherent in human work.

Flexibility and Customization

How often does your product design change? If you offer a wide range of customizable options or are in a rapidly evolving industry, the adaptability of manual assembly equipment and a skilled workforce provides a significant competitive advantage.

Making the Right Choice for Your Application

Ultimately, the decision is not about which method is universally “better,” but which is the right fit for your product, volume, and business strategy.

- Choose Manual Assembly if: You are producing in low volumes, have a high degree of product customization, are in the prototyping stage, or have a limited initial budget.

- Choose Automated Assembly if: You are mass-producing a stable product design, require high levels of precision and quality control, and are focused on long-term cost reduction and scalability.

In many modern facilities, a hybrid approach is used, where automated systems handle the repetitive, high-volume tasks while human operators perform final assembly, customization, and quality inspection. A crucial part of this process, whether manual or automated, is the final stage where all components and sub-assemblies are brought together. This often involves a detailed box build assembly process, encompassing everything from enclosures and wiring to testing and final packaging.

Conclusion: An Informed Decision for Future Growth

The debate over automated vs manual assembly equipment is a strategic one. By carefully evaluating your production volume, quality requirements, budget, and need for flexibility, you can select the approach that best aligns with your operational goals. Just as we empower homeowners to make confident choices about their energy future, understanding these core manufacturing principles empowers businesses to build a foundation for sustainable growth and success.