Budgeting for manufacturing operations is a high-stakes balancing act, and few areas have as many variables as system assembly. From a simple enclosure to a complex, multi-board electromechanical product, understanding the system assembly equipment cost is fundamental to project success and profitability. Without a clear picture of the potential investment, you risk derailing timelines and eroding margins before the first unit is even built.

Table of Contents

This comprehensive assembly equipment price guide is designed for professionals navigating the complex landscape of manufacturing solutions in 2025. We will break down the key factors that drive pricing, explore different tiers of equipment, and uncover the hidden costs you need to factor into your budget. Whether you’re considering setting up a new line or outsourcing to a partner, this guide will provide the clarity needed to make a confident financial decision.

What Factors Influence System Assembly Equipment Cost?

The price of system assembly equipment is not a one-size-fits-all figure. It’s a spectrum influenced by your specific product, volume, and quality requirements. Here are the primary drivers that will determine your final investment.

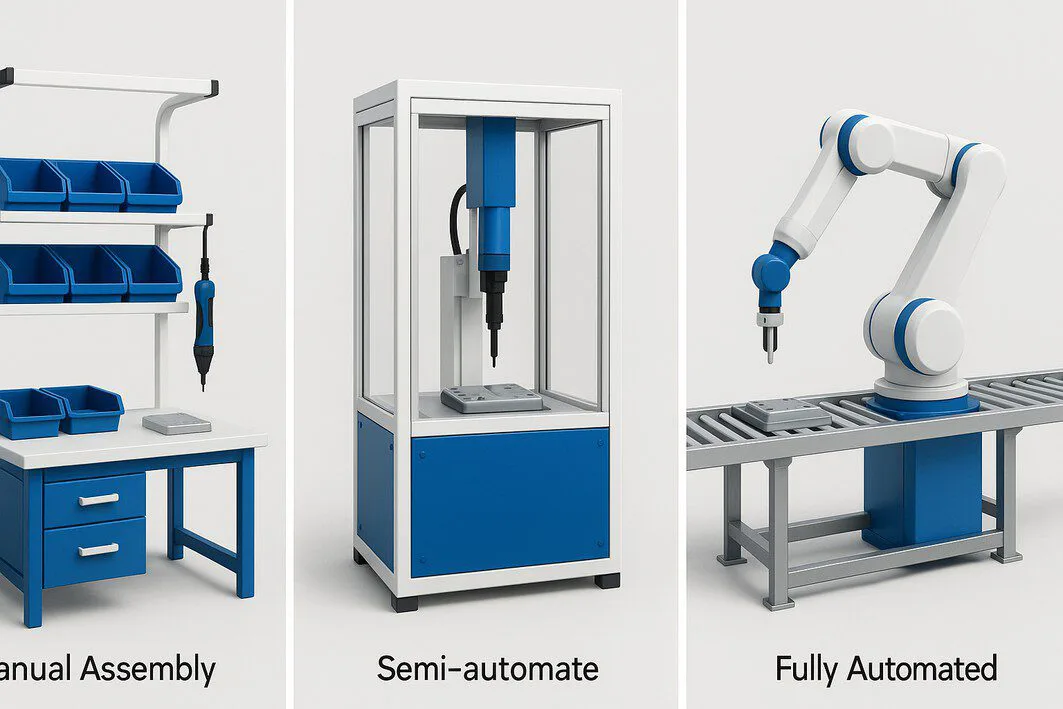

Level of Automation

This is the single most significant cost driver.

- Manual: Relies entirely on human operators using basic hand tools. The equipment cost is low, but labor costs are high and scalability is limited.

- Semi-Automated: A mix of manual labor and specialized machines that assist with specific, repetitive tasks like screwdriving, wire processing, or dispensing.

- Fully Automated: Utilizes robotics, conveyors, and integrated systems to handle the entire assembly process with minimal human intervention. This requires the highest upfront capital investment.

Complexity and Scale of Assembly

A simple two-part enclosure with a single PCB requires far less sophisticated equipment than a multi-layered system with numerous connectors, cables, daughterboards, and mechanical components. The more intricate the assembly and the higher your production volume, the more you’ll need to invest in specialized and robust equipment.

Required Tools and Technology

The specific tools needed for your product directly impact cost. This can range from basic necessities to highly specialized machinery:

- Basic: Torque drivers, presses, wire strippers, soldering stations.

- Advanced: Automated optical inspection (AOI), robotic arms, conformal coating machines, laser welders, and custom jigs or fixtures.

Quality Control and Inspection Systems

Ensuring every unit meets specification is non-negotiable. The equipment needed for quality control can range from simple visual inspection stations to advanced, automated systems like X-ray inspection for verifying solder joints within a sealed unit. Higher quality demands often equate to a higher equipment cost.

A Breakdown of Costs: From Box Build to Full Automation

To give you a clearer picture, let’s explore the estimated price ranges for different tiers of system assembly equipment.

Manual Assembly Stations

- Description: An ergonomic workbench equipped with task lighting, power tools (like electric torque drivers), soldering irons, and component bins.

- Use Case: Ideal for low-volume production, prototyping, and highly customized products where flexibility is more important than speed.

- Estimated Price Range: $2,000 – $15,000 per station.

Semi-Automated Equipment

- Description: Standalone machines designed to automate a single, repetitive step in the assembly process. Examples include automatic screwdriving systems, wire cutting and stripping machines, and programmable dispensing robots for adhesives.

- Use Case: Perfect for increasing throughput and consistency on specific tasks without the cost of a fully automated line.

- Estimated Price Range: $10,000 – $75,000 per machine, depending on its function and sophistication.

The Cost of Automated Assembly

- Description: A fully integrated line featuring robotic arms, PLCs (Programmable Logic Controllers), conveyance systems, and in-line testing and inspection. This is a turnkey solution designed for high-volume, low-mix manufacturing.

- Use Case: Mass production of consumer electronics, automotive components, and medical devices where speed, repeatability, and minimal labor are critical.

- Estimated Price Range: $150,000 – $2,000,000+. The cost of automated assembly varies dramatically based on the number of steps, types of robots, and level of integrated testing.

Understanding Box Build Assembly Cost

For many companies, the most practical approach isn’t buying equipment but outsourcing the entire process. The box build assembly cost is the price a contract manufacturer charges to complete your final assembly. This cost bundles labor, equipment use, quality control, and project management. The process involves much more than just putting parts in a box; it covers everything from installing sub-assemblies and PCBs to routing wire harnesses and performing final product testing. To learn more, see this comprehensive overview of the box build assembly process. By working with a partner, you leverage their existing investment in top-tier equipment and expertise.

Hidden Costs to Factor into Your Budget

The price tag on the equipment is only the beginning. A smart budget accounts for these often-overlooked expenses that are critical for long-term operational success.

- Installation and Setup: Complex automated lines require professional installation, calibration, and integration, which can be a significant one-time cost.

- Training: Your operators will need thorough training to run, troubleshoot, and maintain the new equipment safely and efficiently.

- Maintenance and Consumables: A maintenance schedule is vital. Budget for spare parts, lubricants, and other consumables needed to keep machinery running smoothly.

- Software Licensing: Many advanced systems run on proprietary software that may require annual licensing fees or paid updates.

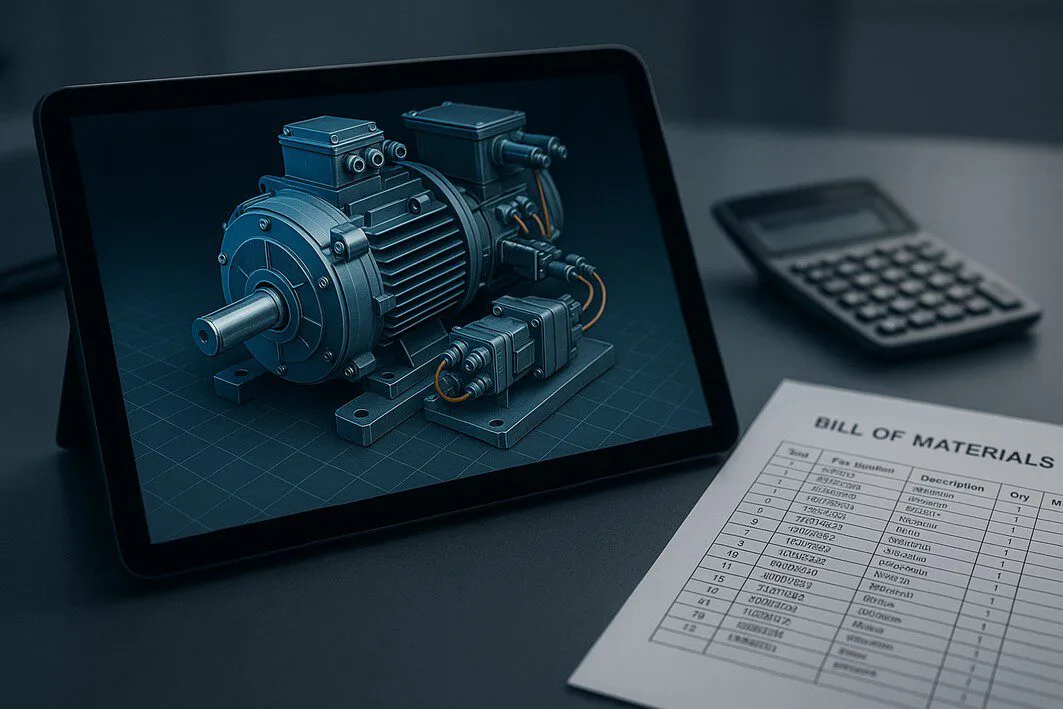

How to Get an Accurate Quote for Your System Assembly Needs

Whether you’re buying equipment or partnering with a contract manufacturer, the quality of your quote depends on the quality of the information you provide. Our experience in providing transparent quoting and cost analysis has shown that the following elements are key.

- Provide Detailed Project Specifications: A complete Bill of Materials (BOM), 3D CAD models, and detailed assembly drawings are essential.

- Define Testing Requirements: Clearly outline all functional, electrical, and quality tests to be performed.

- Discuss Volume and Forecast: Be clear about your expected production volume (per batch and annually) as this heavily influences the choice between manual, semi-automated, or fully automated solutions. An expert partner can analyze this data and recommend the most cost-effective path forward.

- Work with an Experienced Partner: A partner with a robust knowledge base and a focus on comprehensive solutions can help you identify potential manufacturing challenges early and optimize your design for efficient assembly, ultimately saving you money.

Conclusion: Investing Wisely in Your Assembly Process

Determining your system assembly equipment cost is a critical step in planning for manufacturing success. The investment can range from a few thousand dollars for a manual workstation to millions for a fully automated line. The right choice depends entirely on your product’s complexity, production volume, and long-term business goals.

By understanding the key cost drivers, accounting for hidden expenses, and providing detailed specifications, you can create a realistic budget and make an informed decision. For many, partnering with a full-service assembly expert provides the fastest and most reliable path to market, granting you access to state-of-the-art equipment and specialized knowledge without the massive capital outlay.

“