In modern manufacturing, transforming a collection of individual components and printed circuit boards (PCBs) into a fully functional, market-ready product is a complex and critical process. This is where system assembly equipment comes into play, serving as the backbone of production lines across countless industries. But what is system assembly equipment exactly? It encompasses the diverse range of machinery, tools, and automated systems used to build, enclose, and finalize a product after the initial PCB assembly is complete.

Table of Contents

This guide will provide a comprehensive overview of the essential assembly equipment that powers today’s manufacturing. We will explore the different types of machinery, their roles in the production process, and the key factors to consider when investing in these foundational technologies. Whether you are scaling production or refining an existing line, understanding this equipment is the first step toward achieving greater efficiency, quality, and profitability.

What is System Assembly Equipment?

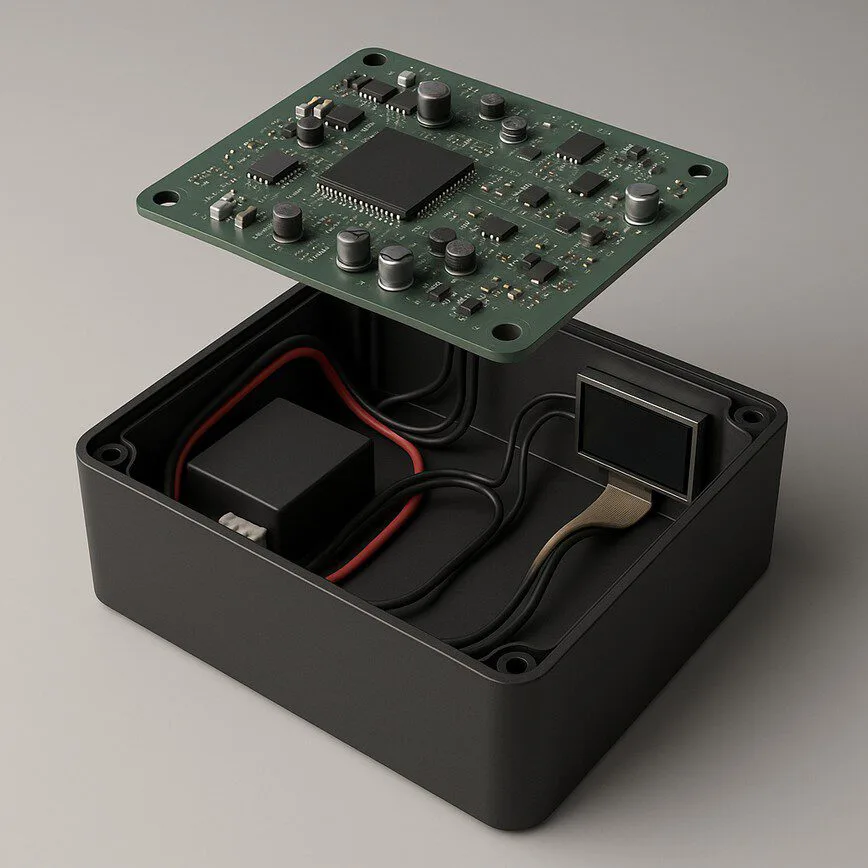

At its core, system assembly equipment refers to all the hardware used in the final stages of product manufacturing, often called system-level assembly or box build assembly. While PCB assembly focuses on populating circuit boards with electronic components, system assembly takes those completed boards and integrates them with all other necessary parts—such as enclosures, cables, power supplies, user interfaces, and mechanical hardware—to create a finished product.

The primary function of this equipment is to perform these integration tasks with precision, speed, and consistency. This can range from simple manual workstations to highly sophisticated robotic assembly lines, all designed to ensure the final product meets exact design specifications and quality standards.

Key Types of System Assembly Equipment

A modern system assembly line is a carefully orchestrated ecosystem of specialized machinery. While the exact configuration varies based on the product, several core types of equipment are fundamental to the process. These include:

- Automated Screwdriving and Fastening Systems: These use robotic arms and torque-controlled drivers to fasten components with perfect precision and speed, ensuring every connection is secure without damaging sensitive parts.

- Dispensing and Sealing Equipment: For products requiring protection from moisture, dust, and vibration, this equipment applies adhesives, sealants, and gaskets with extreme accuracy to ensure a perfect seal.

- Press-Fit and Insertion Machines: These apply controlled pressure to insert components like connectors and pins without damaging the PCB or the part itself, a task that is difficult and risky to perform by hand.

- Conveyor and Material Handling Systems: The arteries of the production line, these systems move units seamlessly from one station to the next, minimizing manual handling and setting the pace of production.

- Testing and Inspection Stations: Integrated throughout the line, these stations (including In-Circuit and Functional Testers) verify electrical performance and use vision systems to inspect for physical defects, ensuring no faulty units leave the factory.

The Critical Role of Box Build Assembly

The term box build assembly is often used interchangeably with system-level assembly. It specifically refers to the process of creating the “box”—the enclosure or chassis—and integrating all electronic and mechanical components within it. This is far more than just putting a PCB in a plastic case; it’s a multi-step process that can include:

- Installing sub-assemblies and modules.

- Routing and connecting wire harnesses and cable assemblies.

- Installing power supplies, fans, and cooling systems.

- Assembling mechanical components like brackets, frames, and displays.

This stage is where the product truly takes its final form. A successful box build requires a deep understanding of mechanical engineering, electronics, and process optimization. To fully understand the intricacies of this stage, from the specific tools required to quality control best practices, it’s helpful to explore the complete box build assembly process.

How to Choose the Right System Assembly Equipment

Selecting the right equipment is a major strategic decision that directly impacts your operational efficiency and bottom line. Key factors to consider include:

- Production Volume: Are you building ten units a day or ten thousand? High-volume production justifies investment in high-speed automation, while lower volumes may be better served by more flexible, semi-automated workstations.

- Product Complexity: A simple device with few components has very different needs than a complex system with intricate wiring and multiple sub-assemblies. Your equipment must be able to handle the specific challenges of your product.

- Scalability: Will your chosen assembly equipment be able to grow with your business? Look for modular systems that can be easily expanded or reconfigured as your production needs evolve.

- ROI and Total Cost of Ownership: Beyond the initial purchase price, consider the long-term value. High-quality equipment may cost more upfront but delivers a stronger return on investment through lower labor costs, higher yields, and improved product reliability.

Partnering with an Assembly Expert for Optimal Results

Navigating the world of system assembly equipment and processes can be daunting. The sheer variety of technologies and the complexity of integrating them into a cohesive production line require deep expertise. This is why partnering with a manufacturing specialist is often the most effective path to success. An experienced partner brings a comprehensive knowledge base of what works, helping you avoid common pitfalls and select the most effective solutions for your specific product and goals. By understanding the entire product lifecycle and leveraging tools like an ROI calculator, a knowledgeable partner can help you make an informed decision, ensuring your investment in equipment and processes pays dividends for years to come.