Navigating the world of electronics manufacturing can feel overwhelming, especially when trying to budget for a project. One of the most significant variables you’ll encounter is the surface mount technology cost. Whether you’re a hobbyist developing a prototype or a business planning a production run for a new residential solar controller, understanding the factors that drive PCB assembly cost is crucial for success.

Table of Contents

This guide is designed to demystify the financial aspects of SMT. We’ll break down the key components that influence pricing, helping you make a more informed decision with confidence. By understanding what goes into the final quote, you can better plan your project and partner with the right manufacturer.

What is Surface Mount Technology (SMT)?

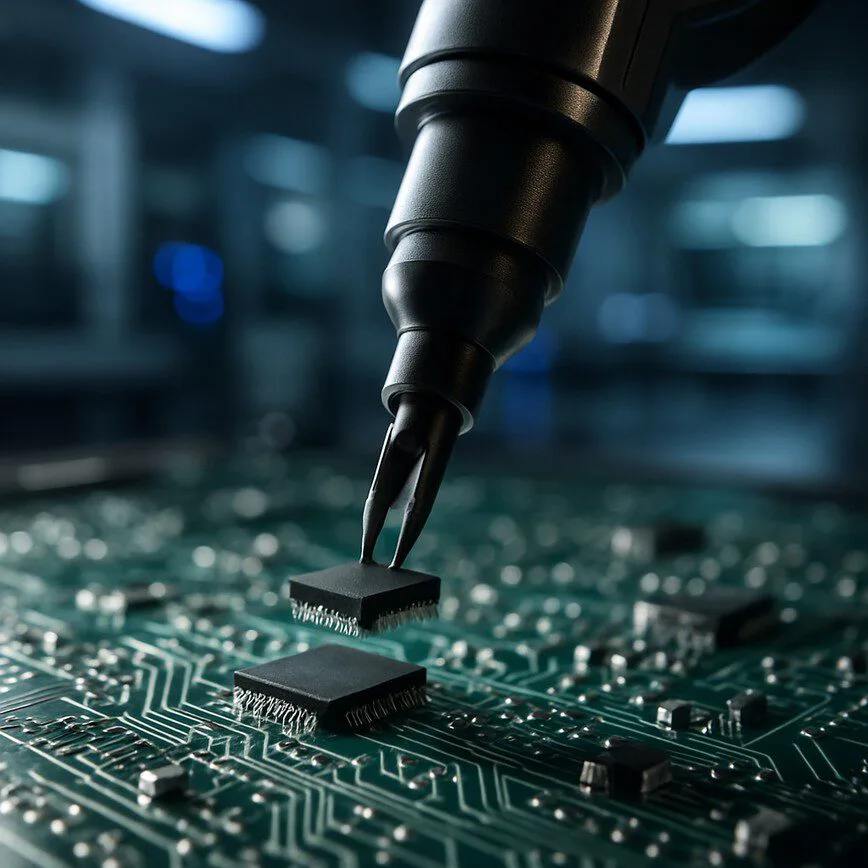

Before diving into the costs, let’s quickly recap what Surface Mount Technology (SMT) is. SMT is the dominant method for assembling electronic circuits. Unlike older methods where components had leads pushed through holes in the circuit board, SMT involves placing components directly onto the surface of the Printed Circuit Board (PCB). This allows for smaller, more densely packed, and highly automated assembly, making it the standard for most modern electronics.

Key Factors Influencing SMT Cost

The final SMT cost isn’t a single number; it’s a sum of several interconnected factors. Here are the primary drivers you need to consider.

Board Complexity and Size

The physical characteristics of your PCB are a foundational cost factor. A simple, single-sided board will be significantly cheaper than a complex, multi-layered board with components on both sides.

- Size: Larger boards require more raw material (laminate), which increases the base price.

- Layers: Each additional layer in a PCB adds manufacturing steps and complexity, directly impacting the cost.

- Density: Boards with tightly packed components require more precise machinery and quality control, which can add to the price.

Component Type and Quantity

The components being placed on the board are a major part of the overall PCB assembly cost.

- Number of Placements: The total number of components to be placed is a primary cost driver. Each placement involves machine time and programming.

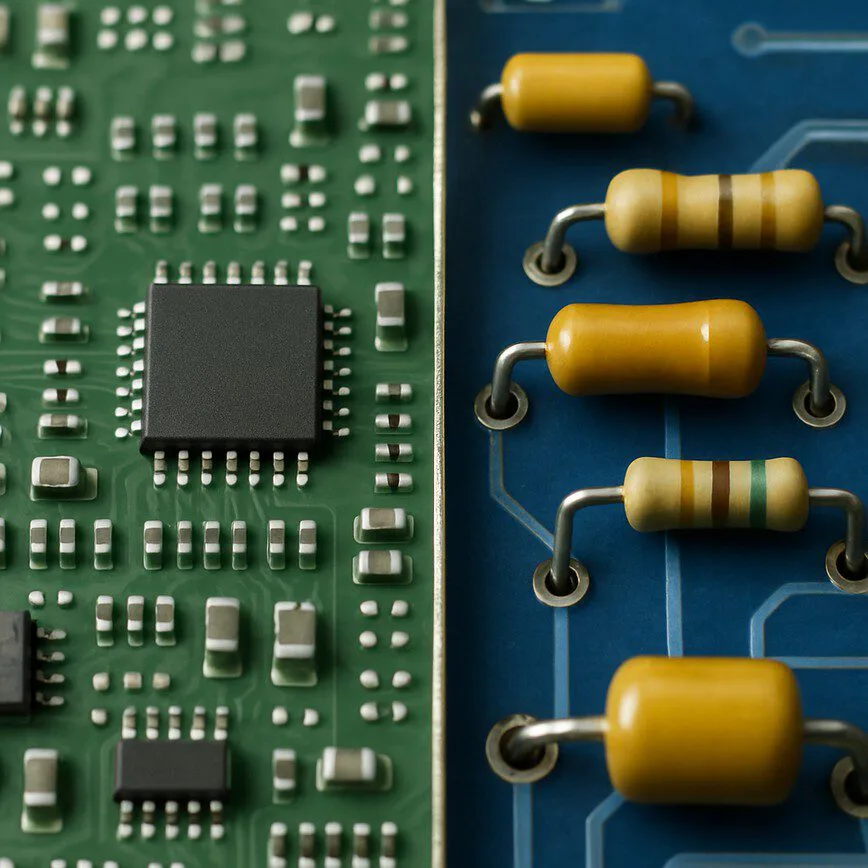

- Component Type: Standard resistors and capacitors are inexpensive and easy to place. However, fine-pitch components like Ball Grid Arrays (BGAs) or Quad Flat No-leads (QFNs) require more sophisticated equipment, specialized inspection (like X-rays), and slower placement speeds, all of which increase costs.

- Sourcing: Whether you supply the components (kitted) or the manufacturer sources them for you (turnkey) will also affect the final price.

Order Volume (Quantity)

Economies of scale play a massive role in the pcb manufacturing process.

- Prototypes (Low Volume): The per-unit cost for a small batch of 1-10 boards will be high. This is because setup costs (NRE – Non-Recurring Engineering) are spread across very few units.

- Production (High Volume): For larger orders (thousands of units), the setup costs are amortized, and the automated nature of SMT leads to a dramatically lower per-unit price.

Stencil and Tooling Costs

To apply solder paste to a PCB in the SMT process, a custom stainless steel stencil is required. This is a one-time NRE cost for each unique board design. While not exorbitant, it’s a fixed upfront cost that is more noticeable on small prototype runs.

Labor and Assembly Process

The complexity of the assembly itself contributes to the cost. A board will require more labor, increasing the overall price, if it involves:

- A mix of SMT and through-hole components

- Manual placement for odd-shaped parts

- Special handling

Testing and Inspection Requirements

How do you ensure your boards work correctly? Testing is a critical but often overlooked part of the surface mount technology cost. Your needs can range from standard to highly specialized processes:

- Automated Optical Inspection (AOI): This is a standard quality control step that uses cameras to check for placement errors.

- X-Ray Inspection: Required for components like BGAs where solder joints are hidden underneath the chip. This is a more expensive, specialized process.

- Functional Testing: A custom test jig may be needed to power up the board and verify its functionality, which adds to the initial engineering cost.

How to Estimate Your PCB Assembly Cost

Getting an accurate estimate requires providing your manufacturer with a complete data package (Gerber files, Bill of Materials, Centroid data). However, you can get a ballpark idea by considering the factors above.

To truly understand the financial impact and return on investment for your project, it helps to have access to powerful tools. Many leading manufacturers provide resources like an ROI calculator to help you make decisions. Leveraging a comprehensive solar knowledge base, for instance, can help you understand not just the cost, but the long-term value your electronics will bring to a residential solar system.

SMT vs. Through-Hole: A Quick Cost Comparison

While SMT dominates, Through-Hole Technology (THT) still has its place, particularly for large, durable components like connectors and capacitors. From a cost perspective, SMT is generally more cost-effective for high-volume production due to its high degree of automation. THT can sometimes be cheaper for very small, simple prototype runs because it avoids the stencil setup cost and can be done by hand. Understanding the core differences between Surface-Mount Technology (SMT) and Through-Hole Technology (THT) is key to choosing the right approach for your project’s budget and goals.

Partnering with the Right Manufacturer

Understanding SMT cost is the first step. The second is finding a partner who aligns with your goals. Look for a manufacturer that not only provides a competitive quote but also offers transparency and expertise. A company that is focused on residential solar solutions, for example, will have a deeper understanding of the specific requirements and challenges of that industry.

An ideal partner acts as an extension of your team, providing a comprehensive knowledge base to guide you through the pcb manufacturing process and helping you optimize your design for cost-effectiveness without sacrificing quality.

Ultimately, while cost is a critical factor, the cheapest option isn’t always the best. A reliable manufacturing partner who delivers high-quality, tested boards on time provides value that goes far beyond the initial quote.