In the world of modern electronics, efficiency, miniaturization, and performance are paramount. At the heart of this evolution is Surface Mount Technology (SMT), a revolutionary method for assembling electronic circuits. But like any technology, it isn’t a one-size-fits-all solution. Understanding the pros and cons of surface mount technology is crucial for engineers, product designers, and businesses aiming to create the next generation of electronic devices.

Table of Contents

This article will provide a balanced look at SMT, exploring its significant benefits and potential drawbacks. By understanding both sides, you can make a more informed decision about whether SMT is the right choice for your specific application.

What is Surface Mount Technology (SMT)?

Before diving into its advantages and disadvantages, let’s briefly define what SMT is. Surface Mount Technology is a process where electronic components are mounted directly onto the surface of a printed circuit board (PCB). This differs from the older through-hole technology (THT), which involves passing component leads through drilled holes in the board and soldering them on the opposite side. SMT components, known as surface-mount devices (SMDs), are typically smaller and allow for a much more compact and automated assembly process.

The Advantages of Surface Mount Technology

The widespread adoption of SMT is no accident. The advantages of surface mount technology have fundamentally changed how electronic products are designed and built.

Miniaturization and Higher Component Density

One of the most significant SMT benefits is the ability to create smaller, lighter, and more complex electronics. Because SMDs are mounted directly on the board’s surface and don’t require drilled holes, components can be placed much closer together. This allows for a significantly higher component density, enabling powerful functionality in incredibly compact devices like smartphones, wearables, and IoT sensors.

Improved Electrical Performance

SMT offers superior performance, especially for high-frequency applications. The shorter leads and compact size of SMDs result in lower resistance and inductance. This reduces signal delays and minimizes unwanted RF interference, leading to faster, more reliable, and cleaner circuit performance—a critical factor in today’s high-speed digital electronics.

Cost-Effective for High-Volume Production

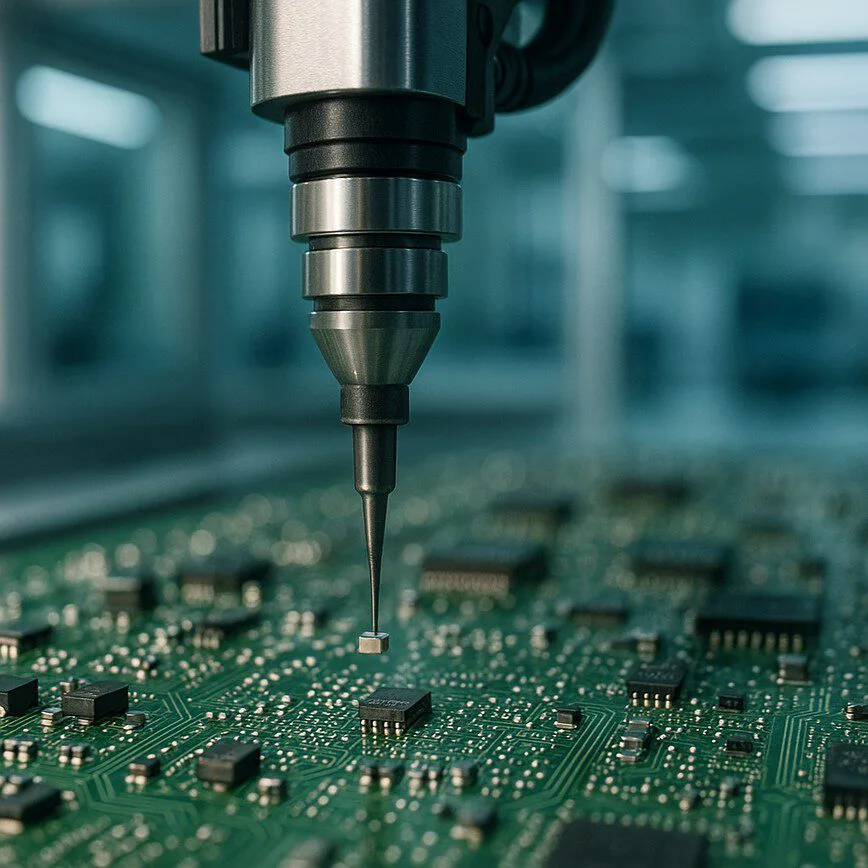

While initial setup can be costly, SMT is extremely cost-effective for medium- to high-volume manufacturing runs. The process is highly automated, with pick-and-place machines capable of placing thousands of components per hour with incredible precision. This speed and automation drastically reduce manual labor costs and the potential for human error, leading to a lower per-unit cost.

Simplified and Faster Automated Assembly

The SMT assembly process is streamlined for automation. Components can be placed on both sides of the PCB, further increasing density and functionality without increasing the board’s footprint. The soldering process, typically done via reflow ovens, is also highly controlled and efficient, ensuring consistent and reliable connections across thousands of boards.

The Disadvantages of Surface Mount Technology (SMT)

Despite its many strengths, SMT is not without its challenges. Understanding the disadvantages of SMT is key to avoiding potential manufacturing and reliability issues.

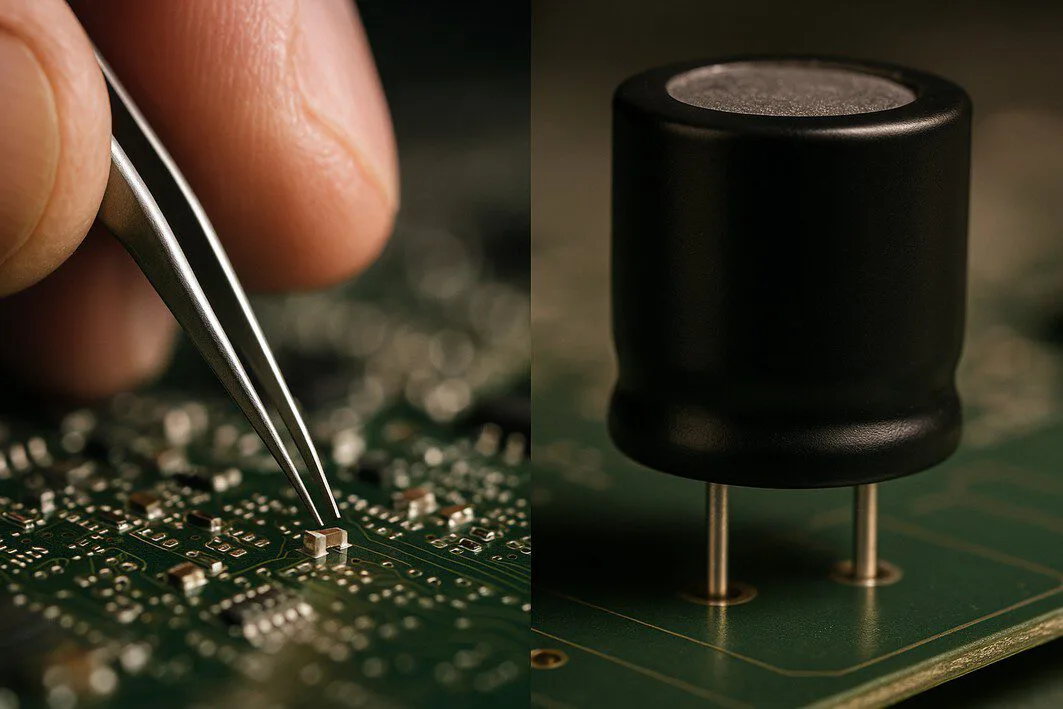

Challenges with Rework and Repair

The small size of SMDs makes manual rework, repair, or prototyping extremely difficult. Repairing a single faulty component often requires specialized equipment like hot-air rework stations and a high level of technical skill. For hobbyists or in low-volume prototyping where modifications are common, this complexity can be a significant drawback compared to the more accessible THT components.

Lower Mechanical Strength

Components mounted with SMT do not have the same robust physical connection to the board as through-hole components. The solder joint is the only thing holding the component in place. For devices that will be subjected to high levels of vibration, shock, or mechanical stress (e.g., large connectors or transformers), the through-hole method provides a much stronger mechanical bond.

Higher Initial Setup Costs

Setting up an SMT assembly line requires a substantial capital investment. Automated pick-and-place machines, solder paste printers, and reflow ovens are expensive pieces of equipment. This high initial cost can be a barrier for small-scale operations, startups, or projects that only require a small batch of PCBs.

Susceptibility to Thermal Stress

The different thermal expansion rates between the SMD components and the PCB substrate can create stress on solder joints during thermal cycling (repeated heating and cooling). While this is a known factor that engineers design for, it can lead to solder joint fatigue and potential failure over time, especially in electronics used in harsh environments with wide temperature fluctuations.

SMT vs. THT: Making the Right Choice

Ultimately, the choice between SMT and THT is not about which is “better,” but which is best suited for the project’s specific requirements:

- SMT excels in applications demanding: Miniaturization, high performance, and cost-effective mass production.

- THT remains the preferred choice for: Durability, ease of manual assembly, and components under high mechanical stress.

Many modern PCBs use a mixed-technology approach, leveraging SMT for dense processor and memory sections while using THT for bulky connectors and components that need to withstand mechanical force. Understanding the nuances of each is a core part of effective electronics design. For those looking to understand where this choice fits into the bigger picture, you can explore a detailed look at the complete PCBA manufacturing process, which further compares these two critical technologies.

Conclusion: Is SMT Right for Your Project?

Surface Mount Technology offers undeniable advantages in density, performance, and automated production, making it the backbone of most modern electronics. The SMT benefits directly enable the sleek, powerful devices we use every day. However, its disadvantages—namely the difficulty of repair, lower mechanical resilience, and high setup costs—mean it’s not the automatic choice for every situation.

By carefully weighing the pros and cons of surface mount technology against your project’s specific goals for size, performance, volume, and durability, you can create a product that is both innovative and reliable.