Look at the smartphone in your pocket, the laptop on your desk, or the complex electronics inside your car. Their incredible power and compact size are made possible by a revolutionary manufacturing method: Surface Mount Technology (SMT). This process is the unsung hero behind the sleek, powerful, and miniature devices that define modern life.

Table of Contents

So, what is Surface Mount Technology? In simple terms, it’s a method for producing electronic circuits where components are mounted or placed directly onto the surface of a printed circuit board (PCB). This guide provides a complete overview of SMT, from its core principles and processes to its advantages over older methods and its role in shaping the future of electronics.

The Core Concept: How Does SMT Work?

At its heart, Surface Mount Technology is fundamentally different from its predecessor, Through-Hole Technology (THT). In the THT process, component leads are inserted through holes drilled in the PCB and then soldered on the opposite side.

SMT eliminates the need for drilled holes. Instead, it uses components specifically designed for this process, known as Surface Mount Devices (SMDs). These SMDs have small metal tabs or end caps that can be soldered directly onto pads on the surface of the circuit board. This seemingly simple change allows for a highly automated, efficient, and space-saving assembly process, enabling the creation of smaller and more powerful electronic assemblies.

The SMT Assembly Process in Detail

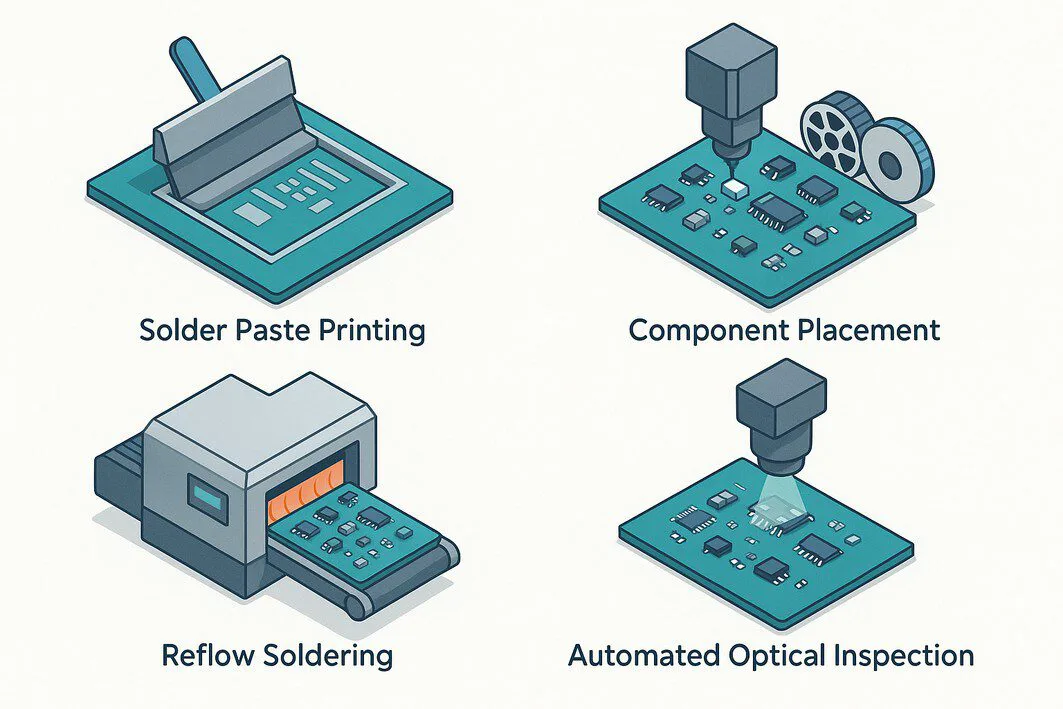

The SMT assembly process is a high-precision operation that relies on automation to achieve speed and accuracy. While workflows can vary, the process generally follows four key steps.

Step 1: Solder Paste Printing

The process begins with a bare PCB. A solder paste—a sticky mixture of tiny solder spheres and flux—is applied to the component pads on the board. This is done using a solder screen or stencil, which is laid over the board, and a squeegee blade presses the paste through the apertures, ensuring it is deposited only where components will be placed.

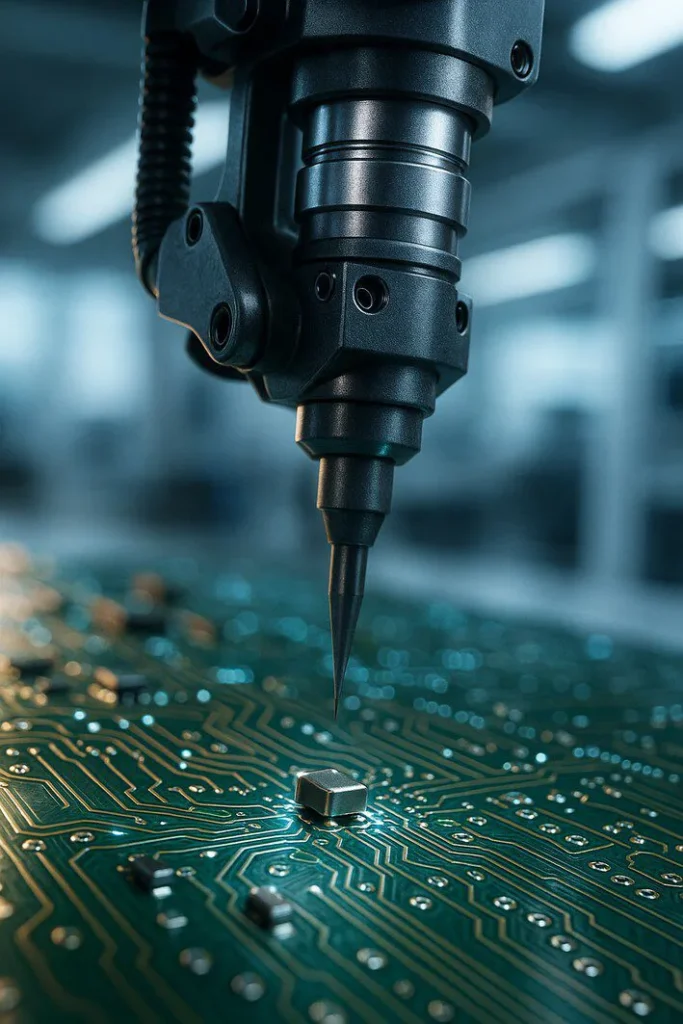

Step 2: Component Placement (Pick-and-Place)

Next, the board moves to a pick-and-place machine. This sophisticated robotic device picks up individual SMDs from reels or trays and places them onto their designated positions on the board. The sticky solder paste holds the components in place temporarily. These machines work at incredible speeds, placing tens of thousands of components per hour with extreme precision.

Step 3: Reflow Soldering

Once all components are placed, the board travels through a long reflow oven. The oven uses a carefully controlled temperature profile to heat the board in several stages. This melts the solder paste, creating strong and permanent electrical connections between the components and the PCB. As the board cools, the solder solidifies, securing the components in place.

Step 4: Inspection and Quality Control

Quality is paramount. After the reflow process, the assembled boards undergo rigorous inspection to detect any defects like misplaced components, poor solder joints, or bridges. This is often done using Automated Optical Inspection (AOI) machines that use cameras to scan the boards and compare them to a flawless reference design, ensuring every board meets strict quality standards.

Key Advantages of Surface Mount Technology

The widespread adoption of SMT is due to its significant benefits over traditional through-hole methods. Our focus on creating efficient, compact, and high-quality electronic assemblies is why we champion SMT for most modern applications.

Miniaturization and Higher Component Density

Because SMDs are much smaller than their through-hole counterparts and don’t require drilled holes, they can be placed much closer together. This allows for an exceptionally high component density, meaning more functionality can be packed into a much smaller physical space. It’s the reason your smartwatch can do more than a room-sized computer from decades ago.

Cost-Effectiveness and Speed

The high level of automation in the SMT process dramatically increases production speed and reduces manual labor costs. While the initial setup for SMT equipment can be significant, the cost per board for high-volume production runs is substantially lower than with THT, making it the most economical choice for mass-produced electronics.

Improved Electrical Performance

The small size and short leads of components result in lower resistance and inductance. This leads to better performance in high-frequency and high-speed circuits, reducing signal noise and improving overall signal integrity—a critical factor in today’s communication and computing devices.

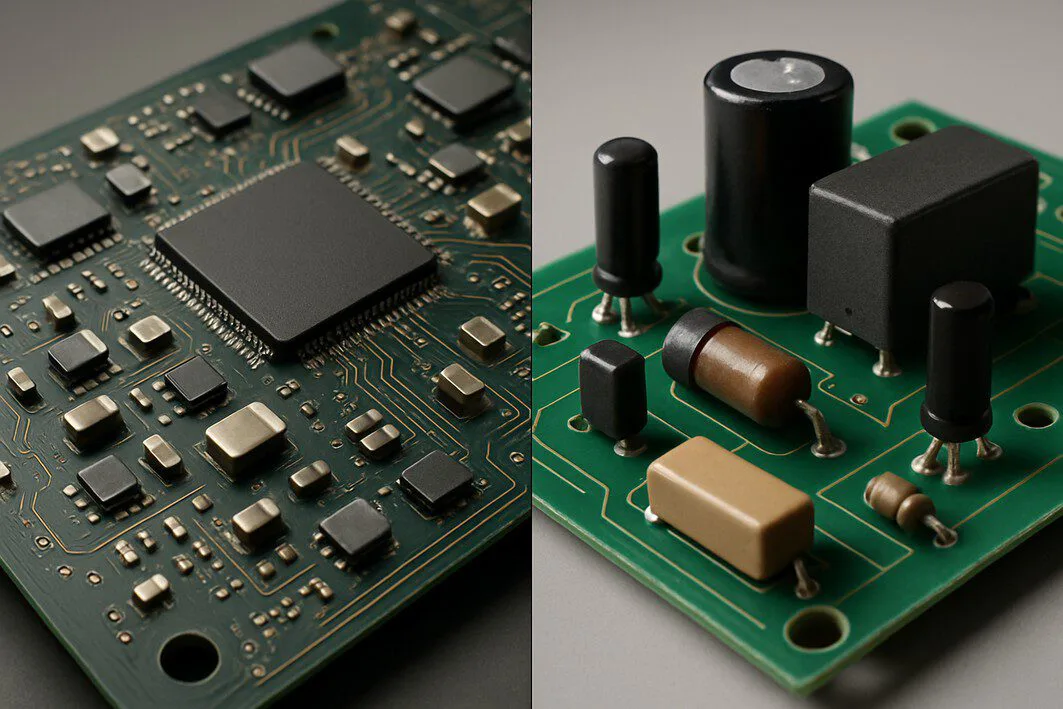

SMT vs. Through-Hole Technology (THT): A Comparative Look

While SMT dominates modern electronics, THT still has its place. THT components are inserted through holes in the PCB, creating a stronger mechanical bond, which is ideal for large, heavy components like transformers or connectors that will undergo physical stress.

Here’s a quick comparison:

- Component Size: SMT components are significantly smaller.

- Board Density: SMT allows for much higher component density.

- Assembly Process: SMT is highly automated and faster; THT is more labor-intensive.

- Mechanical Strength: THT provides a stronger mechanical connection to the board.

- Best Use Cases: SMT is ideal for small, high-performance devices. THT is used for heavy-duty components and prototyping.

Understanding these distinctions is crucial for any project. Choosing the right assembly method is a critical decision within the comprehensive PCBA manufacturing process. Our deep expertise in both technologies allows us to guide clients toward the optimal solution for their specific needs, balancing performance, cost, and durability.

Common Applications of SMT

Today, Surface Mount Technology is ubiquitous. If a device has a circuit board, it almost certainly uses SMT.

- Consumer Electronics: Smartphones, tablets, laptops, digital cameras, and smart home devices.

- Telecommunications: Network routers, switches, and cellular base stations.

- Automotive: Engine control units (ECUs), infotainment systems, and safety sensors.

- Medical Devices: Diagnostic equipment, patient monitoring systems, and wearable health trackers.

- Aerospace & Defense: Avionics, guidance systems, and communication hardware.

The Future of Surface-Mounted Components

The drive for smaller, faster, and more powerful electronics continues to push the boundaries of SMT. We are seeing trends toward even smaller component packages, the development of 3D SMT for stacking components, and the integration of AI into inspection processes for even greater accuracy. As technology evolves, so will the methods used to build it, with SMT remaining at the forefront of innovation.

Conclusion: Why SMT is the Backbone of Modern Electronics

Surface Mount Technology is more than just a manufacturing technique; it’s the foundational process that enables the innovation we see all around us. SMT has become the backbone of the electronics industry by allowing for:

- Miniaturization

- High-speed automated assembly

- Enhanced electrical performance

Understanding its principles is the first step in appreciating the complexity and ingenuity packed into every modern device.

“