In the fast-paced world of electronics and intricate mechanical systems, understanding the product life cycle in the industrial electronics field is crucial for businesses aiming to thrive in competitive markets. From inception to obsolescence, each stage presents unique challenges and opportunities that can significantly impact the success of a product.

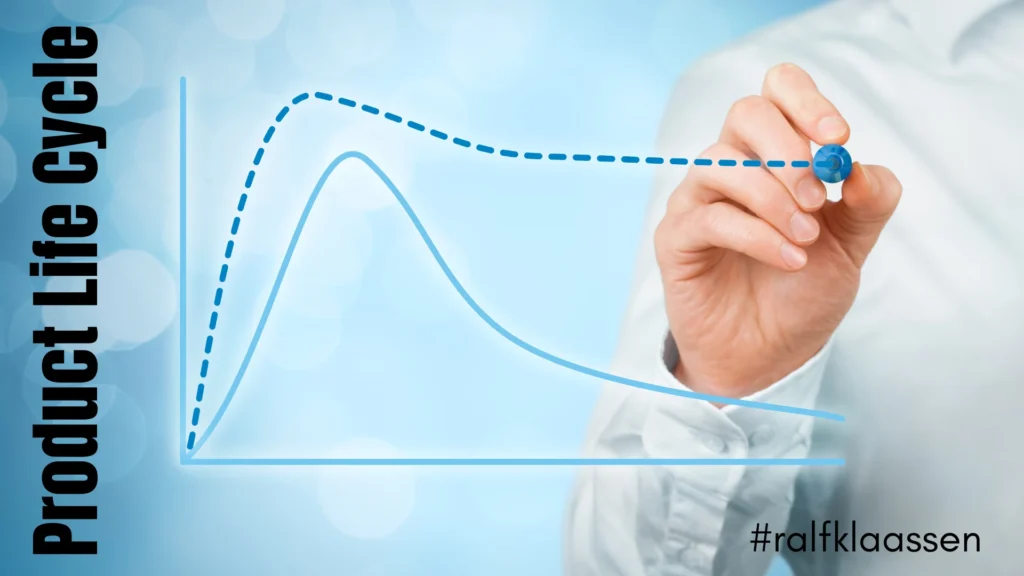

Product Life Cycle

The product life cycle consists of its administration from the initial phases until it stops being manufactured. Therefore, before starting with a new product, the market to which it is going to be addressed must be studied in order to predict its acceptance, although sometimes it is difficult to predict its success, especially if we talk about disruptive elements in the market.

Contrary to what people may think, the design process of an industrial product does not end when it is launched on the market. During the design phases, different versions, tests and prototypes, among others, are made and documented. But even when it reaches the production and sales phase, there are still changes to be made.

The above explains what is known as the product life cycle. The product remains alive beyond the moment in which the design is validated and begins manufacturing. It changes over time, it goes through stages, an analogy of life (product life cycle).

During all these phases, industrial companies must have the process rigorously documented, in order to avoid errors and problems in manufacturing. This allows them to know what has been manufactured at all times with documentation that includes changes and variants.

During the product life cycle for industrial electronics, technical obsolescence is much greater and changes may be imposed by suppliers. Continuous technological advances and changes in models and languages force it to be continually updated.

Design and engineering

Companies in the electronics industry aim to implement innovative ideas and introduce the newest technology to the market first. This puts a lot of pressure on design and engineering teams to create and develop innovative products and services faster and more economically.

To take on these challenges, they resort to simultaneous engineering, which consists of a systematic effort for an integrated design of the product, and its corresponding manufacturing and service process.

Unlike the traditional model in which the design is carried out in a chronological and orderly manner, which conceives the process in stages, and where each phase is carried out one after the other, this methodology allows the different departments (design, engineering, manufacturing, distribution, among others) work in coordination and in parallel, that is, all with common objectives that take into account all the stages that the product goes through, from the original idea to delivery to the client.

Concurrent Engineering, a cornerstone of industrial product life cycle management, involves simultaneous work across various stages, necessitating thorough investment in detailed product definition and planning. This approach facilitates early modifications during the design phase, well before prototype release, thereby significantly mitigating costs.

An essential tenet of Concurrent Engineering is to instill quality right from the inception of the design process, thereby aiming to:

When beginning the design of a product, the first step taken is to make conceptual designs that guide the initial stages of the design, a design that will be carried out with programs, such as computer-aided design programs, CAD, computer-aided engineering, CAE and prototypes with 3D printing, among others.

Using CAD is the best way to have a 3D image of the parts to visualize what the product will be like. That is, if it fits dimensionally what is required, if an attractive design is being made for the client, and also to see the assembly virtually with other pieces.

Using CAE, the designs are analyzed and subjected to movement simulations, interferences are looked for, their ergonomics are studied, and the behavior is simulated with the different forces with which they will work.

Rapid prototyping or 3D printing: Although you see the design on the computer screen, until you have a piece with that design in your hands you do not have a real perception of its dimensions, therefore, prototypes serve to verify a design and even detect assembly defects that have not been previously detected.

These tools can be linked to each other, meaning that any change due to the study in one of them must be reflected in the others.

Finally, when the design is completely defined, it is verified that it meets its objective, so functional prototypes will be made, their manufacturing must be very similar to that of the final product, and in the same materials.

Supply chain

The supply chain is the complete cycle that a product life ccyle goes through, from its pre-production stage until it is a manufactured product and ready to be delivered to the end customer.

Managing the supply chain involves managing the entire process, from obtaining raw materials until the manufactured product reaches its destination, and increasing the value of the product along that journey.

For the supply chain to function fluidly and without interruptions, perfect coordination is required between all the links that participate, directly or indirectly, in the management processes.

This network is made up of the following links: planning, sourcing, manufacturing, delivery and logistics and returns.

● Planning

To ensure the existence of inventories for the entire manufacturing process, a company must analyze demand, plan raw materials and supplies, and calculate production and distribution needs. In this phase, you also have to determine which resources and operations will be produced internally and which will have to be outsourced.

● Supply

The company has to choose the suppliers that supply the raw materials to produce the product. It is necessary to detect the most reliable suppliers who can provide the necessary materials and services within the budget.

● Manufacturing

This is where the different products are made that will later be delivered to customers. This stage involves more than its design or preparation. The company must also test the quality of the products, package them with appropriate security measures, and schedule their delivery.

● Delivery and logistics

Once the products are manufactured, it is time to distribute them from the point of origin to the customer’s location. To do this, the company must implement its logistics plan, which must consider the following points:

❖ Receiving orders

❖ A network of storage locations

❖ Methods of transporting goods

❖ A payment and billing management system

● Return

The last phase of supply chain management focuses on the process of returning damaged or defective products.

In that sense, the company must provide all the facilities so that the return procedure is as agile as possible. Without a doubt, this is a key moment in customer loyalty.

New Products Introduction

The phase of product introduction bridges the gap between design conception and manufacturing realization within the product life cycle. It culminates with the creation of a first functional prototype, marking the transition to a reproducible final product.

Once the new required product and the design have been defined, some parts have even been manufactured to be tested, and although when the project begins, the ways to manufacture the final product are considered, at this point, the study of the technologies and processes. Existing manufacturing methods have been carried out to see which one best suits the production of the product, its production volume and its costs.

Once the manufacturing method is defined, the list of materials to be used is specified, how they will be managed, if the acquisition of new equipment or tools is necessary and if it will be necessary to hire new workers, all of this will help determine the real cost. to manufacture the new product.

Once the factory adapts to the production of the new item, its production is standardized. For this, tests are carried out to determine the times and parameters to optimize the process. Achieving the optimal manufacturing standard is the key to manufacturing a more competitively priced product.

Supply chain optimization

In the context of industrial product life cycle, supply chain optimization aims to minimize operational costs and enhance efficiency by streamlining processes across the supply chain. This objective encompasses reducing risk and ensuring stock availability at each stage, thereby contributing to overall performance enhancement.

To optimize the supply chain, it is important to:

Create safety stocks

To achieve this, it is essential to increase capacity at every stage of the supply chain. Adding safety or reserve stock can help you successfully deal with unexpected increases in demand.

Likewise, time buffers can help to have stock in advance to take into account possible delays in supplier deliveries or shipments.

Review the provider network

Evaluating the network of suppliers will allow us to know the importance of each of them for the company, and the impact that any interruption in their supply could have on it.

Finding the right partners for activities such as transportation or storage improves efficiency throughout the supply chain, improving processes and reducing costs.

Building and maintaining strong relationships with suppliers is essential. Regular communication, with clear objectives, helps maintain and improve these relationships.

Quality control

Companies manufacturing products guarantee the production of higher quality products through:

Establishment of clear and well-defined processes:

Employees are updated and oriented on the changes and best practices that must be adopted in production lines, for which they establish a step-by-step process of how the processes should be carried out.

Giving priority to quality raw materials:

To do this, they ensure that the raw materials are of quality, checking the quality certificates of the supplying company and whether it is duly registered with competent organizations.

Always in accordance with specific legislation:

Companies in the industrial sector, before thinking about any action related to quality control, pay attention to the regulatory standards and what the legislation requires in their segment.

ISO standards, for example, are international standards that provide guidelines to improve the quality of a company with respect to a service and/or product. These help organizations meet the expectations and needs of their customers, continuously manage and control quality in all processes, among other benefits.

Offering training:

Another fundamental point to guarantee quality in the manufacturing of products is the training of teams.

These companies implement continuous training programs with technical and theoretical training, prioritizing the aspects that may represent the greatest risk of failure.

Maintaining clear and effective communication:

Maintaining a clear and effective level of communication with all the professionals involved, so that they are aware of what is being done and why, is also a measure that helps reduce errors and guarantee greater product quality.

Establishing checkpoints:

Control points are any operation or procedure whose failures can be controlled through the use of preventive actions.

The quality control department performs a mapping that defines the stages that have a higher risk of problems occurring, since they must receive additional attention to maintain the desired level of quality.

In this way, when a risk or error is detected, the essential thing is that it be corrected as soon as possible.

Testing

Components of any electronic circuit, it is important to note that, regardless of the application, the common requirement that all PCBAs must meet is to function correctly according to the project specifications and be free of defects.

State-of-the-art electronic circuits include hundreds of components with thousands of solders and interconnections: therefore, it is essential to define rigorous inspection and testing procedures, capable of guaranteeing the quality of the final product.

Regardless of the method chosen, PCBA testing represents a fundamental step in the electronic design process, being able to save a lot of time and money, identifying possible defects that affect the circuit before it reaches final production.

Some PCB Testing Summary:

When electronic circuits were relatively simple, manual visual inspection was sufficient to detect possible problems such as short circuits, imperfect solder joints, interrupted traces, reversed polarity of some components or even missing components.

However, the manual visual inspection technique was not free from problems related to errors made by people when performing repetitive operations.

The first step is to have Automated Optical Inspection (AOI). AOI is currently a verified inspection method, widely used during both preflow and postflow welding, and available on various pick and place machines.

In-circuit test (ICT): This test, performed after the assembly stage, verifies the correct operation and position of each electronic component on the PCB. The test includes checking short circuits, open circuits, resistance, capacitance and other parameters.

Functional test: The functional test is the last step of the inspection and verification process. As its name indicates, its task is to test the operation of a circuit, reproducing the electrical signals capable of stimulating it and measuring the effects produced.

Industrial tests are carried out with the aim of measuring the mechanical and technological properties of the tested product or a part of it under destructive or non-destructive conditions, depending on the properties of use.

Electronics Manufacturing / Complex mechanical

In the Electronics Manufacturing / Complex Mechanical sector, the production process entails two distinct yet interconnected phases.

Initially, the focus lies on manufacturing Printed Circuit Board Assemblies (PCBAs), where intricate electronic components are assembled onto circuit boards. Following this phase, the production transitions into the realm of Complex Mechanical manufacturing. Here, the emphasis shifts towards the assembly of the entire product, incorporating mechanical housing components such as die-cast metals, plastics, and moving parts.

This phase extends beyond mere electronic integration, encompassing the assembly of intricate mechanical structures, integration of liquid and gas components (as seen in printers and other complex devices), and ensuring seamless functionality of the final product.

This integrated approach to manufacturing ensures the cohesive assembly of electronic and mechanical elements, resulting in robust, high-quality industrial electronic products.

Aftermarket

Industrial companies require a range of after-market services to enhance customer satisfaction and prolong the lifespan of their products.

These services include repair and maintenance solutions, facilitating the prompt resolution of any technical issues that may arise post-purchase.

Additionally, companies often provide Return Merchandise Authorization (RMA) services, allowing customers to return defective products for repair, replacement, or refund within a specified warranty period. Beyond reactive support, proactive maintenance contracts may be offered, providing scheduled inspections and preventive maintenance to minimize downtime and optimize equipment performance.

Value-added services such as technical support, training programs, and spare parts management further contribute to meeting customer needs and ensuring long-term product reliability.

By offering comprehensive after-market services, industrial electronic companies can foster stronger customer relationships and differentiate themselves in a competitive market landscape.

With a comprehensive understanding of the product lifecycle for industrial products, I can guide you every step of the way. Whether you’re looking to design innovative products, optimize your supply chain, or manage aftermarket services, my expertise in this field is your resource. Let’s navigate the complexities together and transform challenges into successes.

Don’t hesitate—reach out now and let’s enhance your product lifecycle strategies to ensure your business stays ahead in the competitive market of industrial electronics.